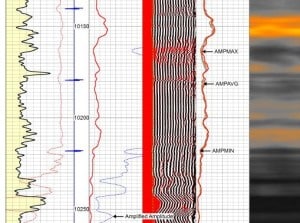

» Cement Bond Log.

RADIAL CEMENT BOND LOG

The radial cement bond tool (CBL) utilizes a single ceramic transmitter, an eight segment receiver at 3ft. spacing and a single receiver at 5ft. spacing to accurately measure the quality of the cement job in a cased hole well environment. The segmented receiver provides a good indication of cement channeling behind the casing.

This cement bond tool is of high-quality steel construction with oil filled, pressure compensated transmitter and receiver sections. The transmitter and both receivers are ceramic to withstand the hostile high temperature of well environments. Upon each transmitter firing, data from all the receivers is digitized and stored in internal memory, then sequentially transmitted to the surface computer.

The digital signal section is capable of transmitting data to the surface from tools run below the radial CBL such as gamma ray, casing collar log (CCL), in-line neutron, compensated neutron or other tool with one or two pulse channels running below the CBL tool.

Transmission of the sonic data to the surface is accomplished by an internal controller which transmits 8 signals from the radial receiver, a composite 3ft. signal (sum of all 8 radial signals), a 5ft. receiver signal, and an internally generated calibration signal. Transmission of the remaining signals consists of digitally encoded data transmitted after the acoustic signals.

The electronics contains firmware that allows the tool to be auto-calibrated inside a calibration fixture. The digital gain is set and all signals stored in memory. These signals can be transmitted uphole on demand by the operator.