Renegade Service: The pioneers of RigLock®, the original hands-free, remote hydraulic wellhead latch assembly

Remove the person from the risk.

Renegade Services continues to innovate and implement new levers of wellsite efficiency and safety with the RigLock remote hydraulic wellhead latch assembly. Developed in conjunction with FHS, RigLock removes wellsite personnel from dangerous situations handling heavy, cumbersome equipment at heights near high-pressure lines.

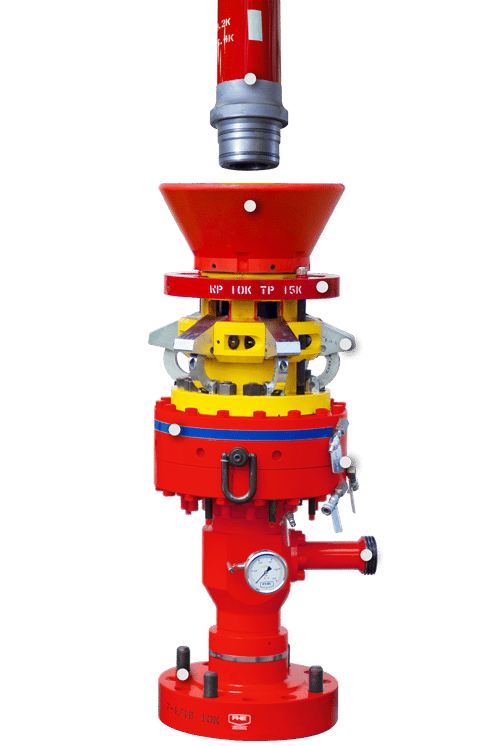

Riglock is a hydraulically-controlled, remote operation device that can connect the lubricator to the well with the flip of a switch. It allows you to remotely connect and disconnect the wireline lubricator. RigLock uses hydraulically operated dogs that lock the lubricator in place and a lockdown ring that mechanically holds the dogs in place. The position of the lockdown ring can be seen from anywhere on location. It also uses a built-in funnel to make it very simple for a crane operator to make a connection.

RigLock utilizes a tapered wedge/spring design and a hydraulically actuated lock ring resulting in industry-leading standards of safety and remote wellsite management sophistication not available with current systems. Crews work from a safe distance, away from the red zone, with but with clear visibility of connection or disconnection operations.

Previously frac operations required the nightcap to be removed manually from the frac tree to stab the wireline lubricator onto the well. This involved a person working on a lift, manually performing the operations. This was done in an exclusion zone, directly underneath a suspended load with hands on the equipment being lifted. RigLock removes the person from the risk.

- Extractor feature can pull and insert the nightcap remotely.

- Decreases time it takes to stab onto the well from 25 minutes to only eight minutes.

- During zipper fracs, wireline operations can proceed from one to well to another while pumping operations continue uninterrupted.

- Optimized RigLock now an integral part of oilfield operations.

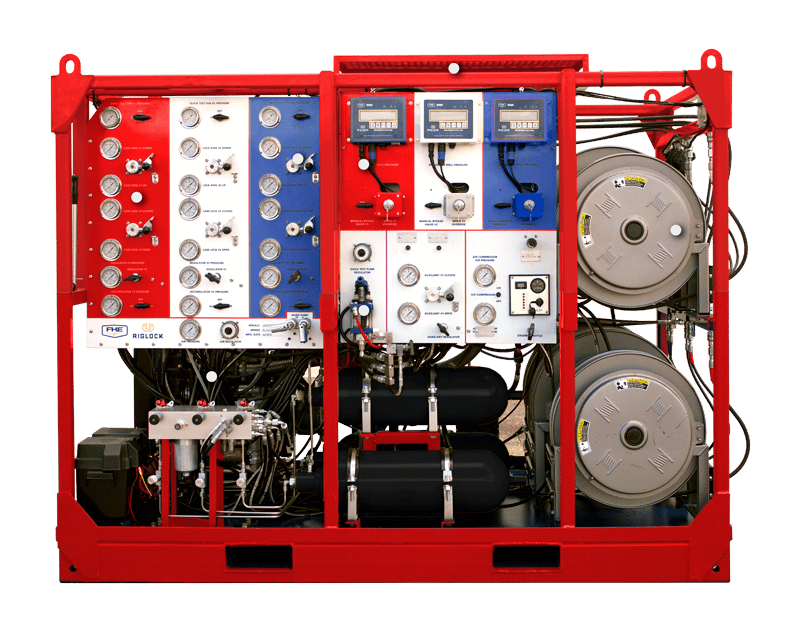

RIGLOCK CONTROL UNIT

At the center of the RigLock system is a simple and safe control unit. The well pressure monitoring system quickly and accurately display operating pressure and includes built-in unintentional unlock prevention. A digital, operator-designed touchscreen with cellular connectivity puts the RigLock control unit at the forefront of wellsite safety and efficiency.

Well Pressure Monitoring System

System Power/Pressure Console

Safety Lockouts

Solar Panel for On Board Power Storage

Retractable Hose Reels

Perkins Diesel-Hydraulic Power Unit with Air Compressor

Nightcap

Contains pressure and keeps foreign material out of the frac tree between stages.

Oversized highly visible entry guide.

This allows the crane operator to quickly spot the sub going into RigLock® from distances of over hundred feet, ensuring proper equipment placement. RigLock® speeds up all well work with quickly connecting and disconnecting.

Mechanical Locking Ring secures the cams.

The locking ring goes over top the cams giving us a secondary lock and thus ensuring the integrity of the connection even during possible loss of hydraulic power.

Cam locks secures equipment connection.

The patented design uses a series of 6 cams to both seat the sub, secure a good connection, and to allow the locking ring to come over the top of it, thus sealing RigLock® to the wellhead.

Manifold to test integrity of connection.

The quick test sub portion of the RigLock® body enables you to test the connection from the control unit on the ground before well pressure is introduced to RigLock®.

Accessible Hydraulic Hook-ups.

Hydraulic quickly connects to RigLock® so that we can quickly make the connections to function the cams the locking rings and the quick test sub. Remote hydraulic actuation keeps technicians away from possible collision or crushing injuries.

Integrated 2 inch 1502 pump-in sub.

This allows for equalization and to pump into the lubricator from below RigLock®.

Flange connection to the wellhead.

These flanges come in different orientations and sizes so that you can easily install RigLock® on any well head.

The Future of RigLock® Innovation

RigLock® changed the oil and gas industry significantly, much like the combustion engine changed the industry of transportation. As we continue to deploy more systems every month, we continue to pioneer new products to expand its efficiency and safety.

Today there are several enhancements to the RigLock® that were not available when the product initially launched. These enhancements to the product make it both safer and more efficient.

Eventually, we believe we will see this package on every well head around the world. We anticipate the RigLock® will fundamentally transform the way completions activities are done on oil or gas well sites.

“We greatly value our relationship with Renegade Services. They provide a quality experience to their customer with a unique and innovative approach.”

—Nick Snoke

Engineered for the Extreme Conditions of High-Pressure Operations

The RigLock® 15K conquers the challenging environments of high-pressure well operations with 3 levels of safety. Well intervention teams, responsible for high-pressure operations, will benefit from increased productivity while improving safety on location. The engineered construction is composed of a limited number of moving parts which reduces maintenance time and improves operations while also increasing usability. With the RigLock® 15K, the adapter or night-cap initiates the connection. The hydraulically actuated lock ring lowers to complete it.

RigLock® 15K Features:

The RigLock® 15K remotely connects surface equipment to the wellhead for high-pressure wells.

- Designed specifically for superior performance on high-pressure well operations.

- 3 levels of safety to protect personnel, equipment, and business relations.

- Four tapered wedges initiate the seal once the adapter or night-cap is received into the RigLock.

- The lock ring hydraulically lowers over the tapered wedges completing the connection.

- The oversized, highly visible entry guide ensures crane operators can properly place equipment.

- By working remotely, technicians lock and unlock the RigLock® from a safe distance eliminating the possibility of injury.

RigLock® 15K Control Unit Features:

- Advanced sensors with light indicators ensure proper closure to prevent operators from applying pressure prematurely.

- The powerful, lightweight VMAC hydraulic driven air compressor generates 140 PSI and produces 30 CFM.

- Powered by a Tier 4 Final diesel engine that runs clean and quiet.

A RigLock® is Ready for You

Let’s start the conversation about how the RigLock wellhead latch and ball drop system and Renegade can work for you.