Case Study: Plug and Abandonment Proceeds After Expansions

Case Study:

Pennsylvania DEP grantS permission for operator to P&A well After Expansion Service

CONDITION:

This Pennsylvania well was scheduled for plug and abandonment, however, gas flow in the annulus prevented the operator from starting the process. All gas migration and pressure had to be eliminated before the Pennsylvania Department of Environment Protection (DEP) would let P&A operations commence. Previous attempts at stopping the gas flow with traditional squeeze cement jobs proved unsuccessful.

PROBLEM IDENTIFICATION:

The operator contacted Renegade Services. After reviewing well problems, Renegade recommended its Local Expander technology, which expands the casing into the cement and blocks the path of any unwanted gas flow.

SOLUTION & RESULTS:

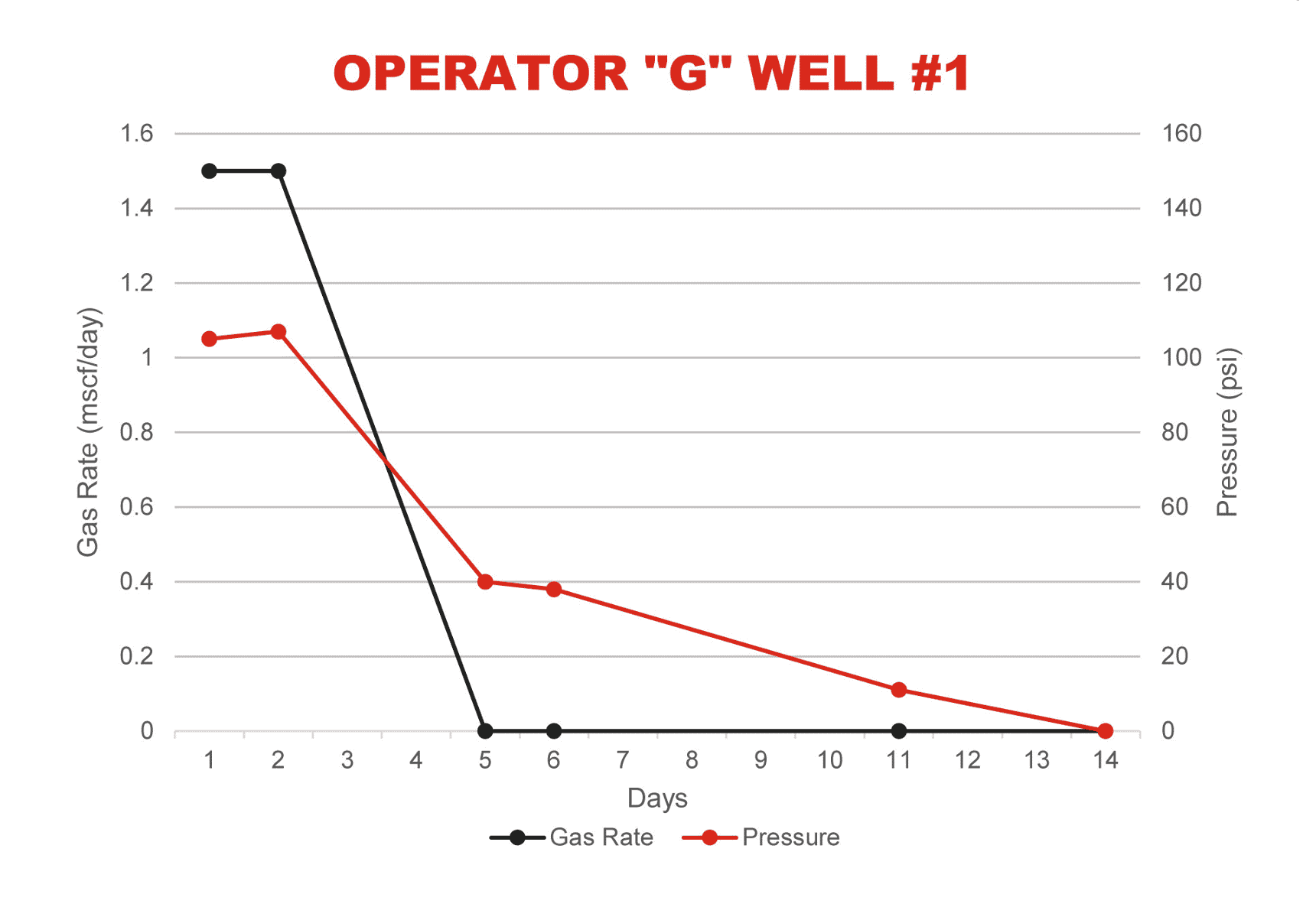

Utilizing Local Expander technology, Renegade created two sets of three expansions. The first set of expansions was performed at depths of 3369, 3370 and 3371 ft while the second set was at 2069, 2070 and 2071 ft, successfully sealing the annulus. The gas rate dropped from 1.5 mscf/day to zero flow after five days while the pressure rate decreased from 105 psi to zero psi after 14 days. Upon reviewing these successful results, the Pennsylvania DEP granted permission for the operator to P&A the well.