As the US has grown oil and gas production to record levels, interdisciplinary parties have expressed concern with the current administration’s decision to reduce regulations governing methane processing on well-sites.

The Environmental Partnership1, a cohort of 65 oil & gas production companies, representing every basin in the US (and globe for that matter), with the simple mission of collectively monitoring and reducing air emissions, including methane and VOCs.

Their mission statement is:

To continuously improve the industry’s environmental performance by taking action, learning about best practices and technologies, and fostering collaboration in order to responsibly develop our nation’s essential natural gas and oil resources.

Even with the US dry gas production totals in 2018 exceeding 30,438 bcf annually, up from 27,291 bcf per day in 2017, it is impressive that the leak rate from surface equipment is 0.16% and decreasing with continued best practices efforts across 78,000 well locations 2, 3.

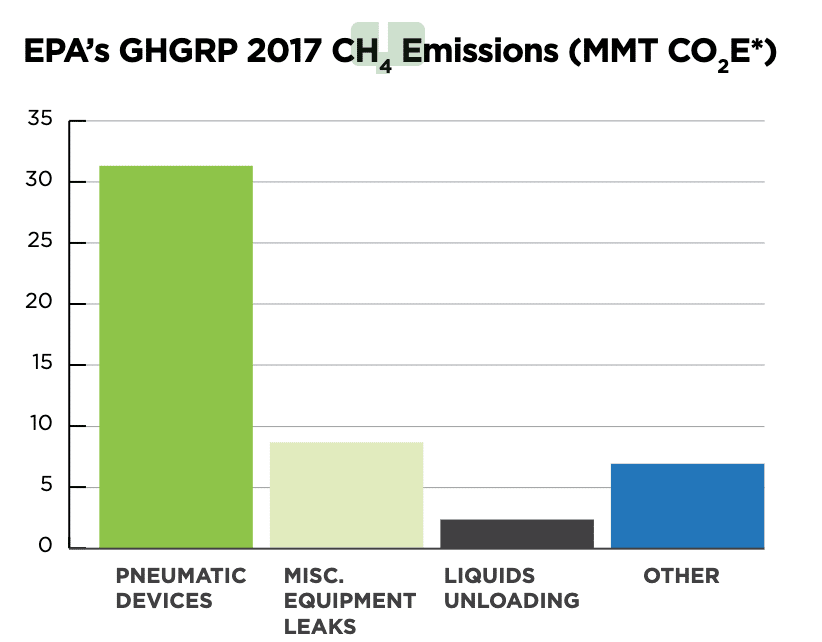

In those efforts, there is a strong emphasis on implementing latest leak detection technologies (including portable), replacing pneumatic bleeding devices that make little to no effort to process vent gas, and improving processes involving the manual transfer of liquids from wells. The Environmental Partnership and companies within it agree that they all can continue to drive the number of leaks down further with on-going participation.

In conclusion of the report, it is great to see the industry collective being as proactive as possible in this initiative. We would like to use this opportunity to go one step further and look at the complications involved with downhole leaking. Unwanted issues of gas getting to surface through micro-annuli behind casing and fractures in casing causing leaks can present unwanted processing concerns that take away from typical production operations.

Our Local Expansion Tool™ is a cost-effective solution that can have repeated services applied through the length of a wellbore without leaving any deployable tools downhole. The simple crimping of casing to close the annuli gap and strengthening casing has been found to eliminate surface casing vent flow and sustained casing pressure situations.

Adding a downhole dimension to The Environmental Partnership with efforts toward eliminating downhole venting in the most cost-effective way possible is a discussion we would love to have! We know this is a solution the industry has been demanding for some time now and we want to cement our legacy in gas containment and pioneering responsible industry practices.

Contact form submission from fraclock.com