RWLS Specialty Services Canada – Local Expander

LOCAL EXPANDER™ ANNULAR SQUEEZE TOOL

Proven annular zonal isolation using localized casing expansion – Gas migration is no longer a threat to well integrity or economics of developed assets.

Natural departure from a perfect application of any service is inevitable in the oil & gas business. Whether problems exist from the last well on the pad resulting in poor hole cleaning from reused mud, variability in perfectly centralized casing throughout the well, displacement rates that are slightly off, or thermal expansion cycles between cement-casing bond, there is a myriad of factors that can contribute to the start of micro-annuli permanently forming and getting worse during the well lifecycle.

When traditional cement remediation methods have maximized their effectiveness with operational tradeoffs and economic compromises, where do you turn? Until now, there has been no alternative to permanent-fixture casing expansion.

3.62″

5.62″

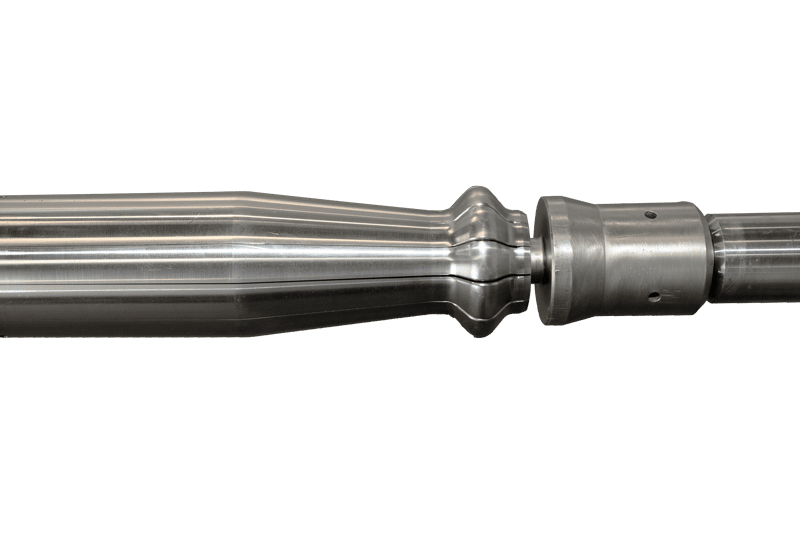

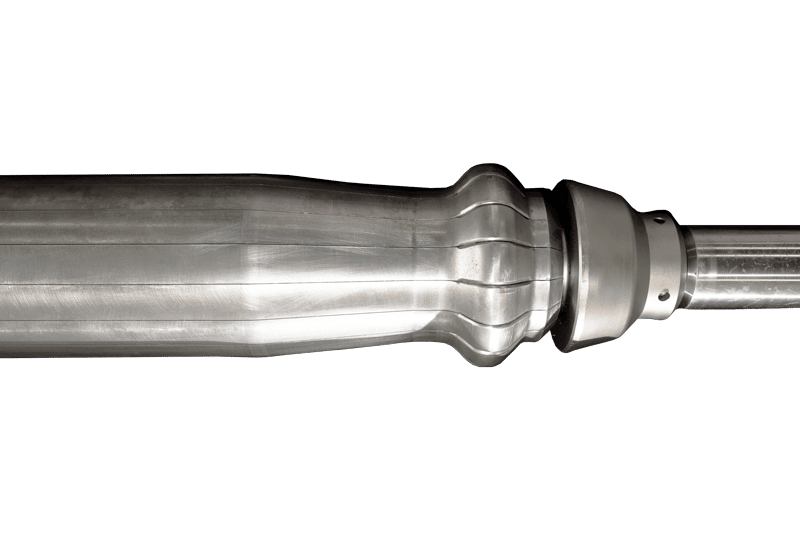

Local expansion is a simple way to stop the unwanted gas flow while correcting unintended annular sections. This one-run tool deployed by a electric-line operator leverages a telescoping cone that expands a radial set of hardened knuckle-bent fingers.

These fingers have a variable displacement distance allowing the flexibility of correcting a gradient of annuli along the wellbore. From small gaps, to areas where both casing and cement require plastic deformation to create a seal and prevent gas flow. Moreover, the exact same process can be quickly repeated at any target interval for engineered redundancy to fully eradicate all micro-annuli and backside gas flow problems with confidence.

HOW IT WORKS

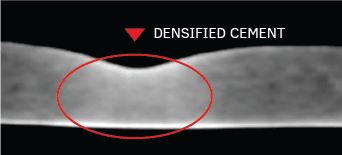

The Local Expander™ applies an actual squeeze to the existing cement by expanding the casing internally.

- Fingers at the top end of the tool are pressed outward by an actuated cone.

- The fingers expand the casing locally.

- Due to the pressure of the ring on the cement, a ring shape is pressed into the casing. The pressure ring extends to the micro annulus

- RESULT: The cement is locally densified, and any gaps or small channels are sealed.

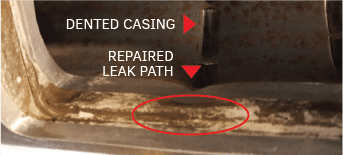

DENTED 7″ CSG X 9-5/8” CSG.

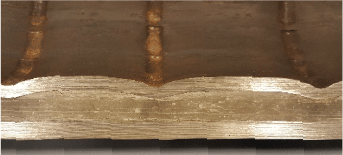

CUT-OUT SAMPLE OF REPAIRED ANNULUS

CT SCAN SHOWING THE DENSIFIED CEMENT

CONVEYED VIA ELECTRIC WIRELINE

The tool creates a series of crimps in the casing that eliminate the micro-annulus. By using an electric line and having a one-run tool, the Local Expander has achieved the same results as a conventional squeeze but at a fraction of the cost and effort.

SAFETY

Safety concern for workover operations is also significantly minimized with the implementation of the Local Expander. Crimping casing close to the surface allows crews to work under much safer conditions knowing without having to handle unwanted gas simultaneously.

PLUG AND ABANDON

Wells scheduled to be permanently taken out of service often lack the economic persuasion required to match the level of urgency as the start of the life cycle. For this reason, the annual inventory of wells to plug at the minimal possible expense dictate abandonment practices. Until now, there has not been a service on the market available to ensure pressure buildup won’t become a public problem. The Local Expander is the trusted choice for scheduled P&A because it can affordably conquer a burdensome issue that is commonly overlooked and ignored. With the Local Expander, P&A liability is significantly minimized with certainty in gas migration prevention practices.

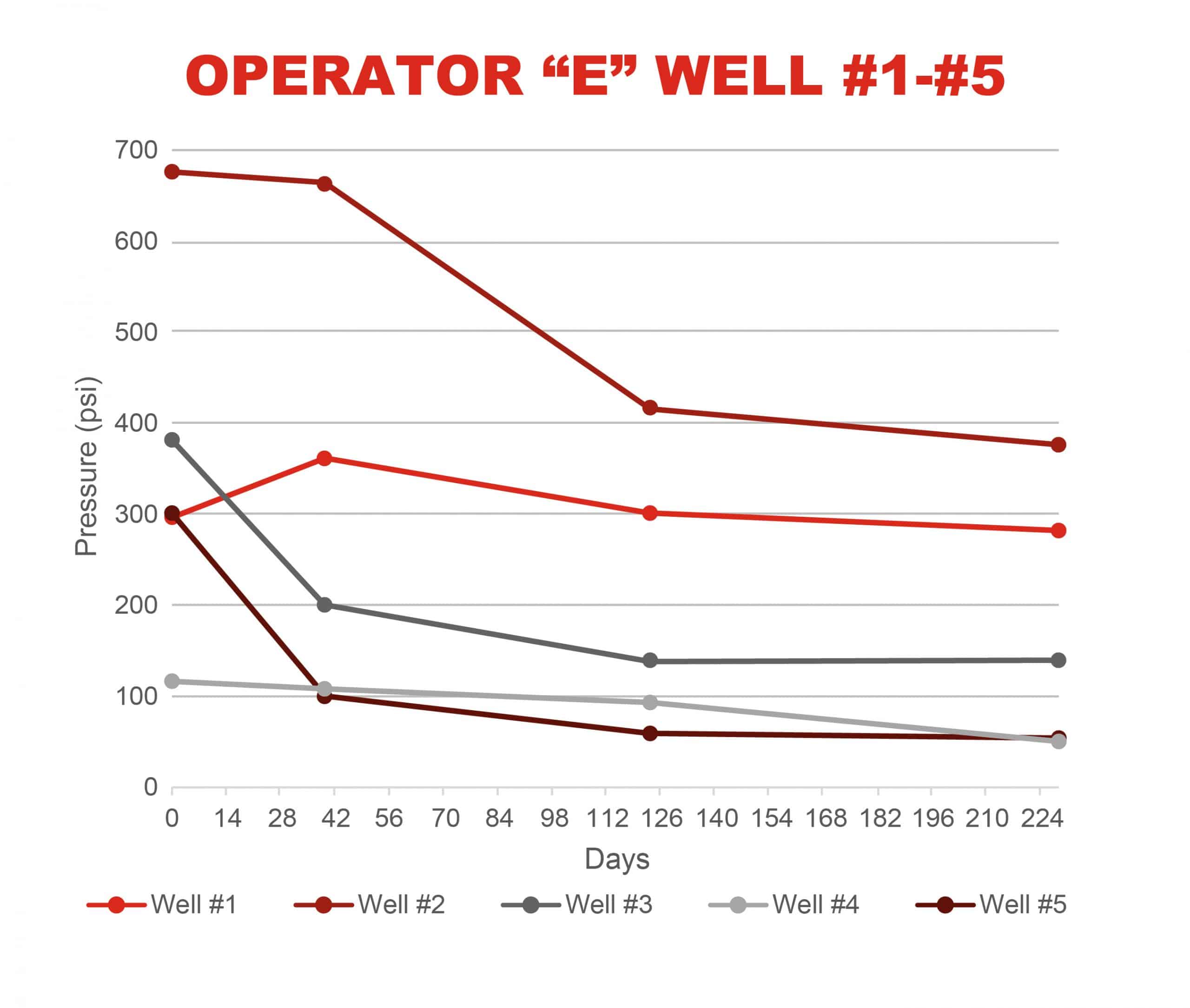

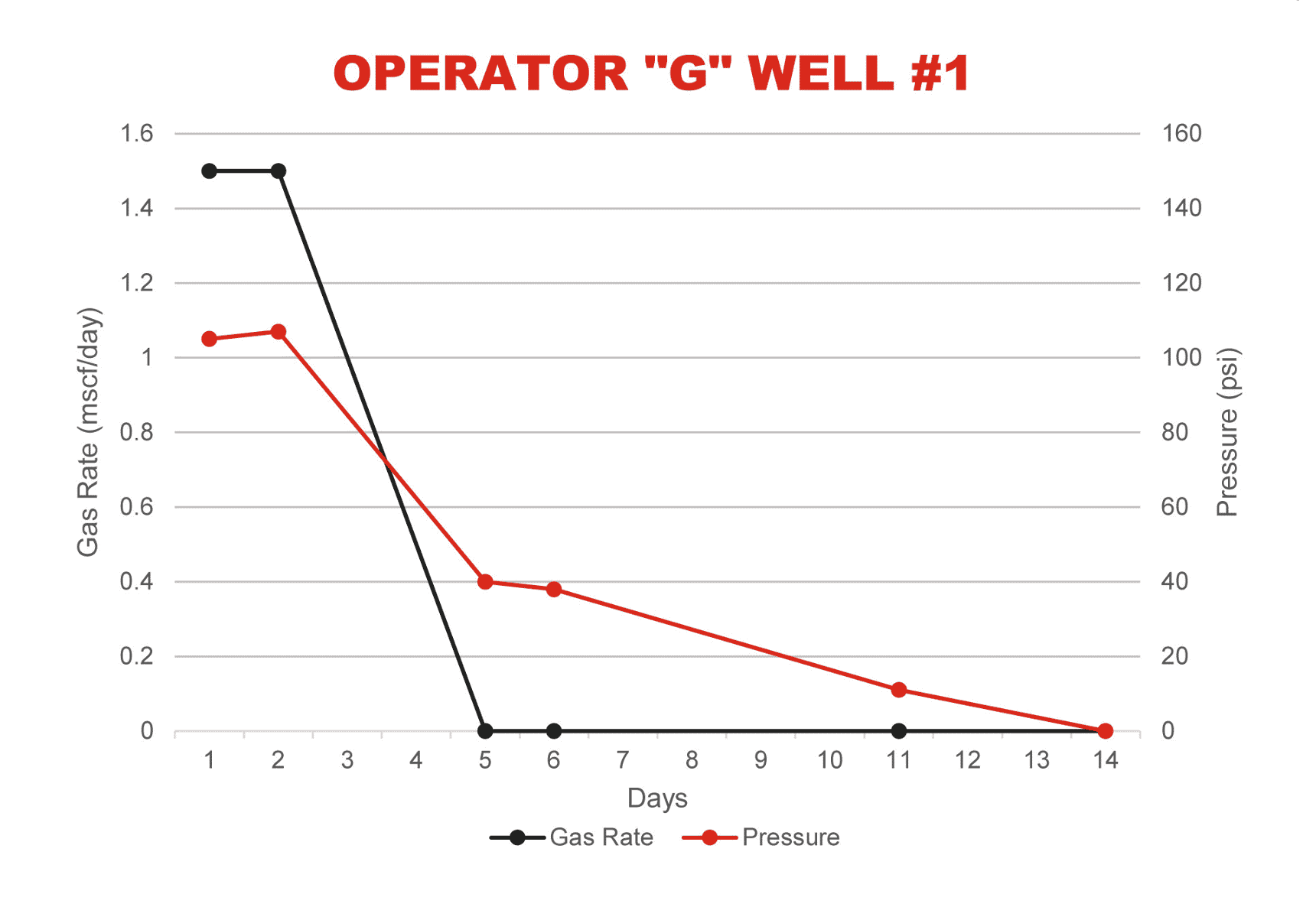

REAL RESULTS

CASE HISTORIES

Case Study: Backside pressure in Pennsylvania well reduced to zero utilizing Local Expander™ Annular Squeeze Tool

Case Study: Pennsylvania DEP grants permission for operator to P&A well after expansion service

SHELL CANADA IN GROUNDBIRCH STOPS GAS ON A DIME IN MONTNEY BASIN

The Local Expander has exceeded expectations in recent field tests with the Shell Canada Production Team, stating after the first two wells with the Local Expander, they reduced SCVF from 500 litres/day to 0.00 litres/day. They are expecting to fully eradicate gas on future wells and have built the Local Expander into their programs as a service they can’t operate without.

REGULATORY

The Local Expander is the preferred solution for regulatory departments because it repairs micro annulus without the use of chemicals and perforation. RWLS Specialty Services is working with the Regulatory bodies in Western Canada, Saskatchewan, Alberta and British Columbia, to name a few, to advocate the importance of eliminating this type of issue by finding a means to mitigate stray gas migration from the beginning.

Environmental

Because there are no explosives, permanently deployable tools, products, or chemicals left behind, the Local Expander leads the industry in an alternative service that leaves no trace beyond the intended service. Furthermore, keeping unwanted gases and liquids in the ground instead of permeating to the surface on the backside of the casing has always been the preferred choice.