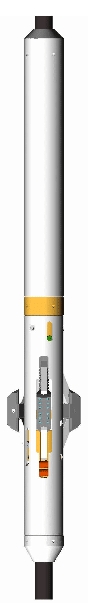

IDC Tool

The Insulation-Displacement Contact (IDC) tool is designed to limit or control the movement of a tool string within the wellbore. This may be required to prevent a logging tool being blown up-hole, along the wellbore by fluid flow, or to hold a tool in place on an incline.

Special slips are available to enable the IDC to act as a gun braking system in the wellbore. The arms of the IDC provide an axial resistance to movement within the wellbore of approximately 300lbs, depending on well pressure. The tool is addressable and therefore multiple IDC tools can be deployed within a string.

The only restriction on placement is that each tool should have direct access to a cable conductor. The IDC requires only one conductor and ground for activation and employs a robust, field proven telemetry system designed for fail-safe operation.

The tool’s electronics can withstand up to 1000vac/1000vdc on its operating conductors. In the event of loss of communication to the tool, it can be withdrawn from the well through restrictions by closure of the load spring or shearing of the arm retaining pins.

APPLICATIONS

- Highly Deviated Wells

- Logging

- Tractor operations

- High-flow PL

- Oriented Perforating

- Gun Braking System

24/7 CONVEYANCE SOLUTIONS FROM RENEGADE FOR EVERY APPLICATION

Call us today for a live presentation and equipment consultation.

The Service Company You Hire Matters

Greaseless Line

» During traditional wireline operation, the line is subject to contact with multiple segments of casing, collars and wipers. Each touch point increases the friction applied to the line. Because it does not use collars, wipers and tubes, greaseless line drastically reduces friction and tension resulting in lower line tensions during pump-down operations.

RENEGADE SERVICES USES GREASELESS LINE FOR Environmentally-FRIENDLY SUCCESS

During conventional wireline operations the grease that’s pumped into the grease head tends to be spread across location. This creates a greater environmental impact on the site, which either leaves a big mess behind or presents the need to be cleaned up. Communities are increasingly concerned about the environmental impact of drilling and don’t understand the real issues involved. Grease easily slings off of sheave wheels and hangs in the air, creating a major problem everywhere. In many ways, it’s one of the biggest hassles on a frac site.

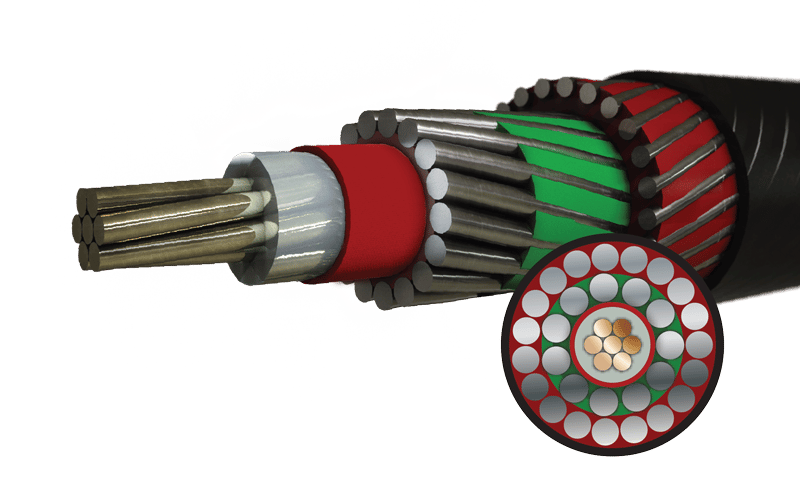

Choosing the right line to run is more important than some may realize. The conventional line has two sets of outer armor wires with a conductor in the middle, but requires a grease injection head to seal the line. It’s messy, inefficient, and not the most environmentally-friendly solution.

Fortunately, this is a headache that’s preventable. Renegade Services uses Streamline® greaseless line, which has been used successfully on thousands runs. Renegade was one of the first to implement it in 2014 and brings years of expertise in its use to every job.

Greaseless line is the best choice for many reasons. Along with the two sets of armor wires around a conductor, the greaseless line is also coated with a non-stick chemical, which eliminates the need for supplemental grease. Even though it has a greater upfront cost, it saves money in the end because there isn’t the additional need to pump in grease to seal conventional lines, and because it is also an environmentally-friendly alternative and there is no clean-up required. This is an increasingly important issue on today’s completions sites.

Count on the experience & efficiency of the right environmentally friendly line for the job. Eliminate the mess from traditional wireline grease and eliminate the need for costly wellsite cleanup when you choose Renegade Services.

» Streamline® Greaseless Line

Renegade has Plug and Perf specialists in every region of the U.S.

Call us today for a live presentation and equipment consultation.