Gunhandler™ LAYDOWN – LIFT ASSIST TOOL

This highly efficient tool—fast becoming indispensable during wireline runs—increases productivity on-site and significantly decreases risk variables associated with operations. Not only is the strain on equipment alleviated but the equipment operators are no longer positioned under a suspended load. Gunhandler is actively being used on pads across the U.S. where crews have reported “feeling crippled when trying to operate without it.”

GUNHANDLER™ WAS DESIGNED BY WIRELINE HANDS FOR WIRELINE HANDS, TAKING THE OPERATOR OUT FROM BELOW SUSPENDED LOADS AND INTO A SAFER, LESS STRENUOUS WORKING ENVIRONMENT.

Safety

Regardless of the amount of safety training, there is still an element of risk during wellsite operations. Reduction in operator fatigue from the use of the Gunhandler™ is pivotal in creating a shop-caliber environment in the field. More focus is put back into service quality rather than heavy lifting. This higher service quality can lead to fewer gun-misfires, less stress on tools, unexpected modes of failure and longer tool life.

- No more manual dolly laydowns/manual lifts

- No more personnel under suspended loads

- Clearly defined “no-go” zone

- Safer, less strenuous gun building zone

- Backup, two-position butt-stock, ratcheting lock feature

- No damage to the cabling at the rope sockets

- Picking up the tool string from vertical positions eliminates all almost flex stress on the tool

- Compact design keeps areas near the wellhead clear – and allows more room to work

- One-person rig-up/down

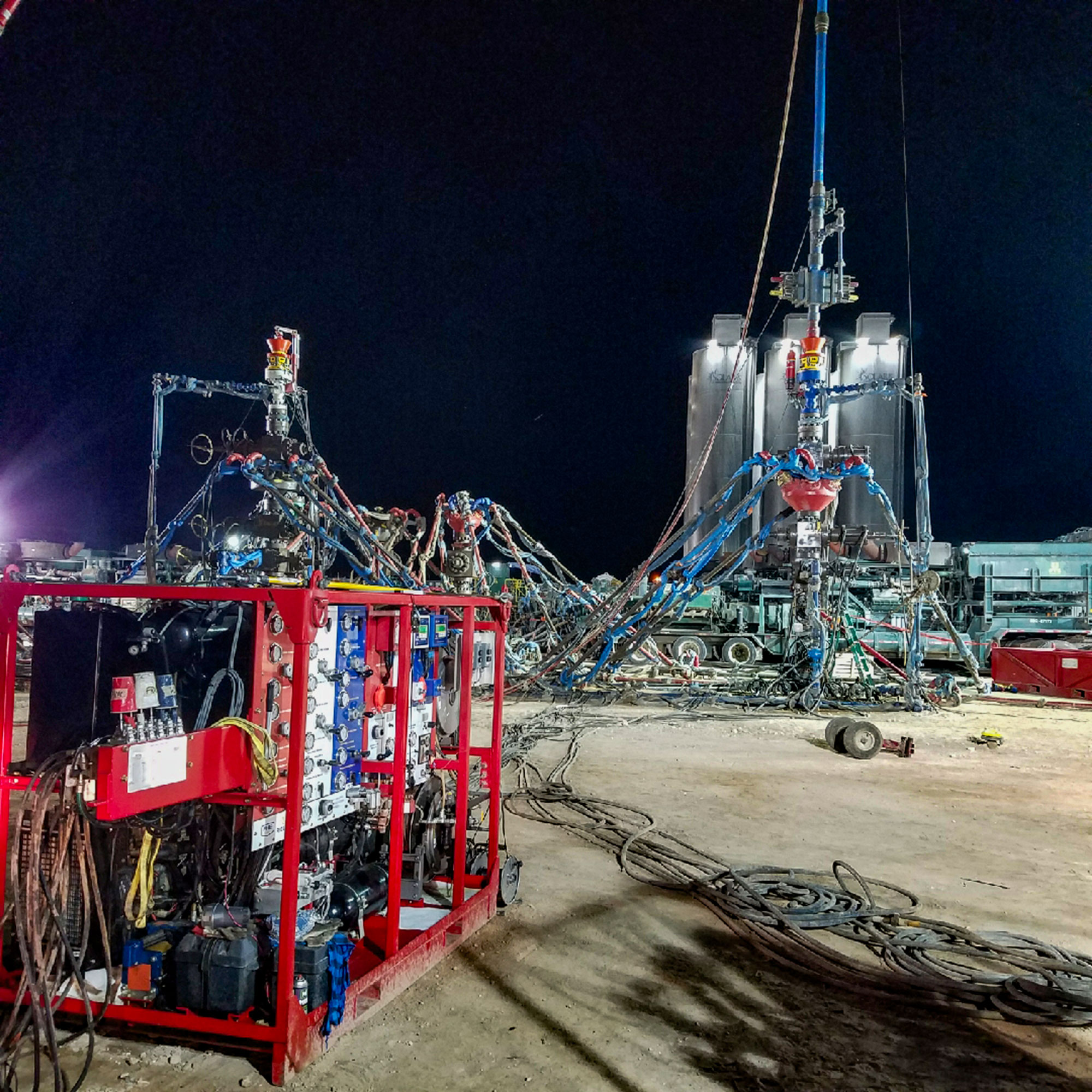

» Gunhandler compact design was made for the congested wellsite area.

Features

The Gunhandler was designed with the equipment operator in mind. The hydraulically actuated lift bunk ranges from horizontal to 80º and eliminates the need for manual dolly laydowns. Taking the operator out of the line of fire removes many of the risk variables associated with near-wellhead operations.The six-pad landing gear not only provides a stable footing for anchored operation but also creates a clearly defined “no-go” zone when lifting or laying down the toolstring.

During Gunhandler operation, the two-position butt stock has a ratcheting lock feature for piece-of-mind, so tools remain secured and is spring-retained in the event that an operator forgets to ratchet it down before use.

- The waist high working surface gives the wireline ground crew a more comfortable and ergonomic working environment.

- Wing legs open at 45° and span a width of 18 ft providing near limitless adjust-ability, a no-go barrier and secure stabilization.

- Compact footprint at only 6 ft wide provides the most efficient use of the allotted square footage for the wireline working area.

- Fully extended to the 80˚ maximum lift, the equipment will stand 23 ft vertical height.

- Gunhandler takes only one crew member to setup, operate and prepare for travel.

- Jack-legs are rated to 8,000 lb and have an 18 in. travel

Increases in the number of stages completed per day can put added strain on operators and increase the risk for potential fatigue-related incidents. The increased frequency of rebuilding of guns is similar to the high volume of repair at the shop level. Gunhandler has an overall height of 42 in. and provides an ideal working height for the operator. Renegade is bridging the gap to assist our field operators by providing shop-like conditions at the wellsite.

INCREASED EFFICIENCY

The compact design of the Gunhandler keeps areas near the wellhead clear and allows operators more room to work. Virtually no added room is needed to place Gunhandler into the work zone, yet it provides the functional capability of 23 ft of vertical support to the tool string. With an overall width of 6 ft, it has advantages over many other industry solutions and allows workers to easily reach tools without strain during a rebuild.

One-person rig-up/down makes the Gunhandler one of the simplest pieces of equipment to setup, run or transport. Variable speed control allows the operator to adjust the rate of the crane operation for maximum precision.

Reduction in operator fatigue is pivotal in creating a shop-caliber environment in the field. More focus is put back into service quality rather than heavy lifting. This higher service quality can lead to fewer gun-misfires, fewer unexpected modes of failure, and longer tool life.

GUNHANDLER – An INNOVATION WHOSE TIME HAS COME

Minimizing risk while driving operational efficiencies is something every operator strives for. Renegade is dedicated to providing turnkey solutions that enhance oilfield safety and efficiency. Call Renegade today to see how Gunhandler can add value to your wireline operations.

Operators feel handicapped working without it. Gunhandler™ is available exclusively from Renegade Services

Call us today for a live presentation and equipment consultation.

RENTALS

Technical: (337) 371-7635

Sales: (325) 267-1693

Office: (337) 321-4145

SERVICE

Sales: (318) 272-8320

Office: (337) 321-4145