GAMMA RAY TRACERS HELP EVALUATE ACID DIVERSION

Gamma Ray Tracers Help Evaluate Acid Diversion, J.L. Taylor, III, et al, Petroleum Engineer International, February 1990.

ABSTRACT

The use of multiple gamma ray tracers has helped evaluate acid diversion in several North Sea completions. The use of multiple radioactive tracers and subsequent logging with advanced gamma spectroscopy techniques offers a cost-effective and convenient method for direct measurement of vital stimulation parameters such as diverter effectiveness.

Productive intervals in the Norwegian sector of the North Sea tend to be quite thick: Danian pay ranges up to 550 ft, and Maestrichtian up to 500 ft. Average porosity can reach 48%, and matrix permeability varies from less than 0.1 to 5 md. Well productivity seems dependent on the degree of natural fracturing, and pressure transient testing derived permeability estimates can be as much as 75 times the matrix permeabilities obtained from core measurements.

Perforations are placed in 10-to 20-ft clusters spaced 40 to 80 ft apart, with a shot density of 2 shots/ft throughout each cluster. The acid stimulation treatments are then pumped in multiple stages, with each stage consisting of a viscous pad, acid, overflush, and diverter (ball sealers are most often employed).

The tracer studies outlined in this article were conducted on six stimulation treatments to determine if the diverter techniques employed result in relatively even treatment of all pay, and to evidence the creation of multiple hydraulic fractures. All evidence suggests adequate diversion usually occurs and new fractures are propagated on each stage.

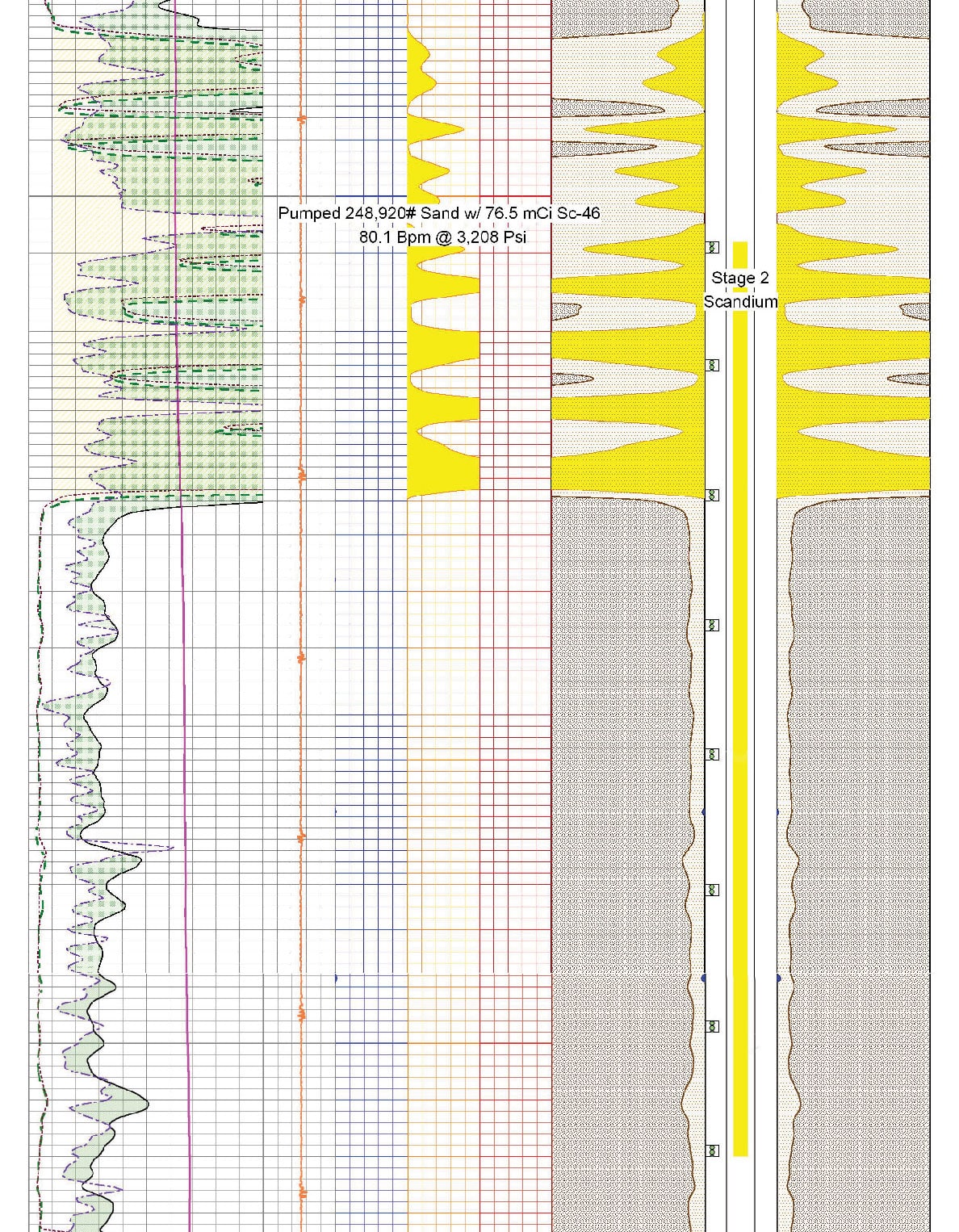

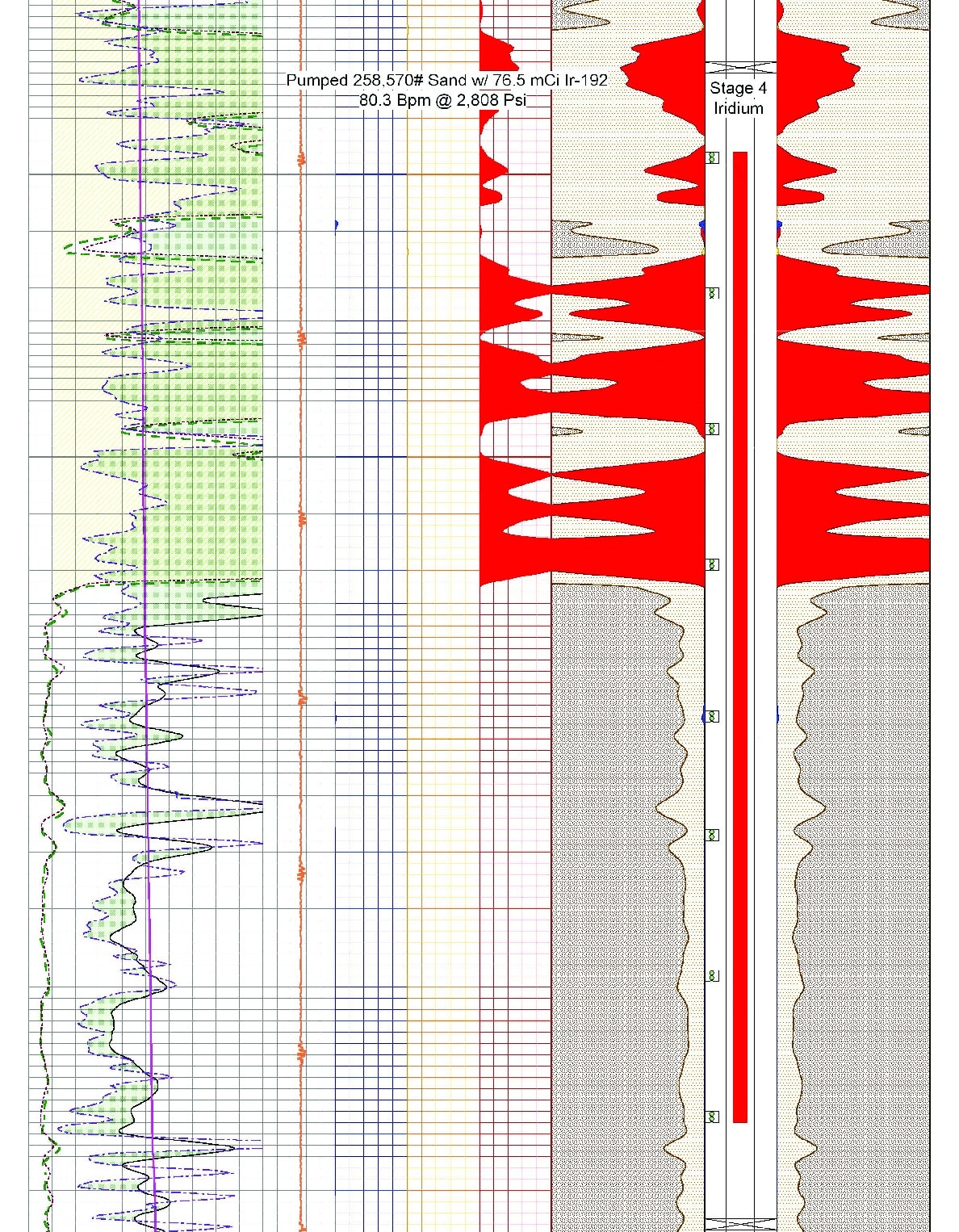

The specific tracer technique used involved the placement of a different discernible gamma emitting tracer in each stimulation stage to determine its relative placement and thus infer the effectiveness of the diverter stages. Three tracers, Antimony (124Sb), Iridium (192Ir), and Scandium (46Sc) were added to each stage to differentiate the placement of up to three stages or groups of stages. Following each treatment, a Prism® log was run to identify tracer placement. A detailed description of the materials used and the tagging and logging techniques were discussed in earlier articles.

The tracers were prepared as ceramic particle encapsulations, with a mean particle size of 0.5 mm. This proprietary preparation exhibits a tracer washoff of less than 0.01% in 28% HC1 at 100xC, and has a specific activity of approximately 0.89 mCi/gm (32.8 MBq/gm) or 0.0014 mCi/particle (0.0527 MBq/particle). The use of these tracers in particulate form was preferred to using soluble forms to minimize environmental concerns of returning radioactive residue to the surface with the flowback of the spent acid. The tracers and the equipment used to inject them into the stimulation process were transported to the well platforms from the UK aboard the service company’s vessel performing the treatment. Generally, about 20 mCi (740 MBQ) of each tracer was injected continuously throughout each acid stage. Specific licensing to perform the radioactive tracer studies was required from Norway’s National Institute of Radiation Hygiene.

The wells were logged using a 1.6875-in. (4.2863-cm) OD Prism tool, which contains a 1-in. by 6-in. scintillation crystal. The logging speed was 500 ft/hour (152.4 m/hour). At each 3-in. (7.62 cm) interval, the entire 256-channel gamma ray spectrum was encoded and transmitted to the surface and recorded on magnetic tape. This data was subsequently processed using the proprietary software on a microcomputer at a log analysis center in Stavanger, Norway. The software mathematically unfolds the gamma ray spectrum to determine tracer yields and indicate the location of individual isotopes along the wellbore. Furthermore, the program determines the lateral tracer placement (inside or outside the casing) by using a photopeak to downscatter ratio.

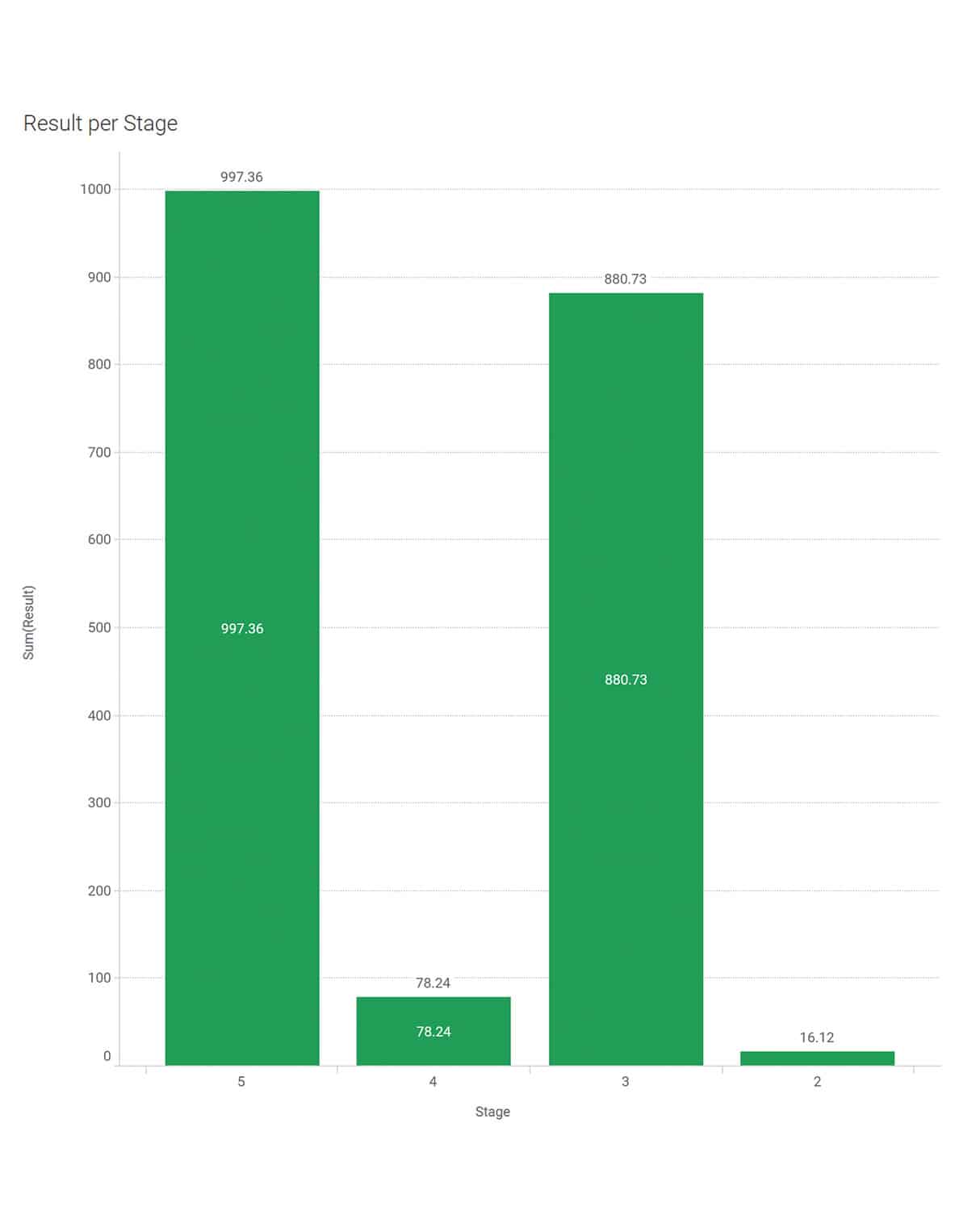

The results of the six tracer studies are presented in tabular form in Table 1. The Prism logs from wells A, B, and C are presented as Figs. 1,2, and 3, respectively.

In summary the following conclusions are made:

Tracer materials of the type and packaging used are effectively placed in the formation and do not flow back into the well. In consequence, reliable Prism data may be obtained in one pass after cleanup flow of the well.

Where the cement bond log indicates effective mechanical isolation of perforated zones in the treated interval and the number of perforations is low, good diversion occurs.Breakdown of both single and multiple zones on individual stages were observed.

Limited fracture heights and formation of multiple fractures occurs.

Tracer material positioned during the early treatment stages is partially stripped away during the later stages. This is particularly apparent when the number of perforations is low and flow velocities will, in consequence, be high.

The logging technique and analysis allows us to determine the placement of isotopes in the presence of radioactive scale.