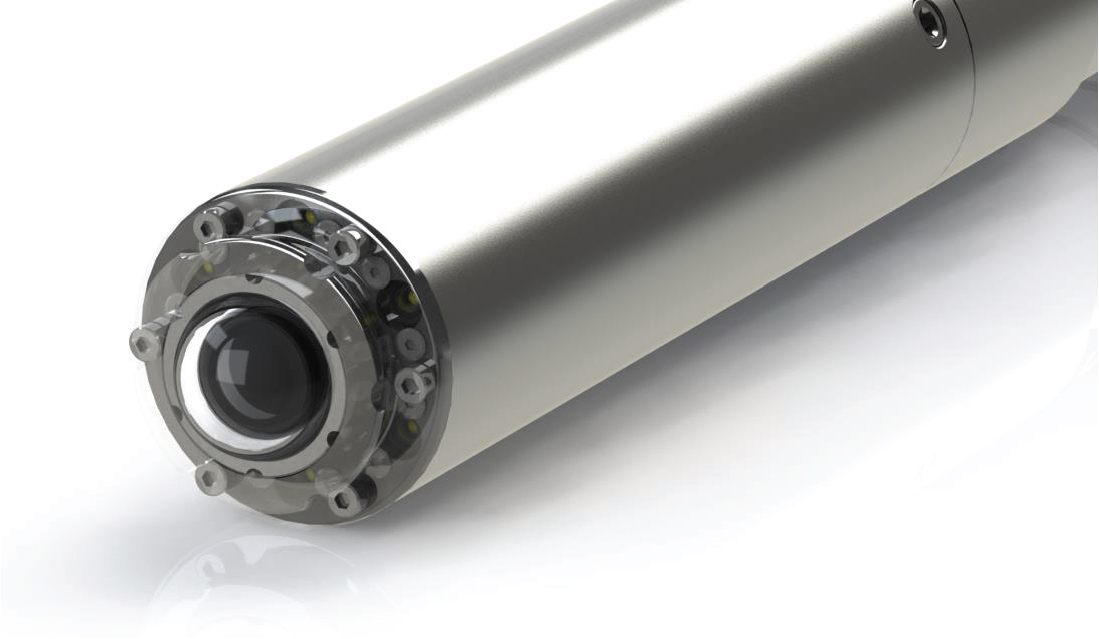

DOWNHOLE INSIGHT™ NUWAV™ CAMERA

NuWAV Downhole Insight Camera: Realtime Wellbore Visualization

When downhole problems occur, solutions are recommended based on the data at hand. Renegade is taking the guesswork out of this process by adding one more piece of critical data.

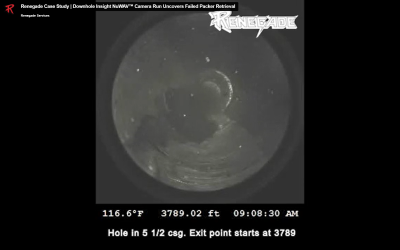

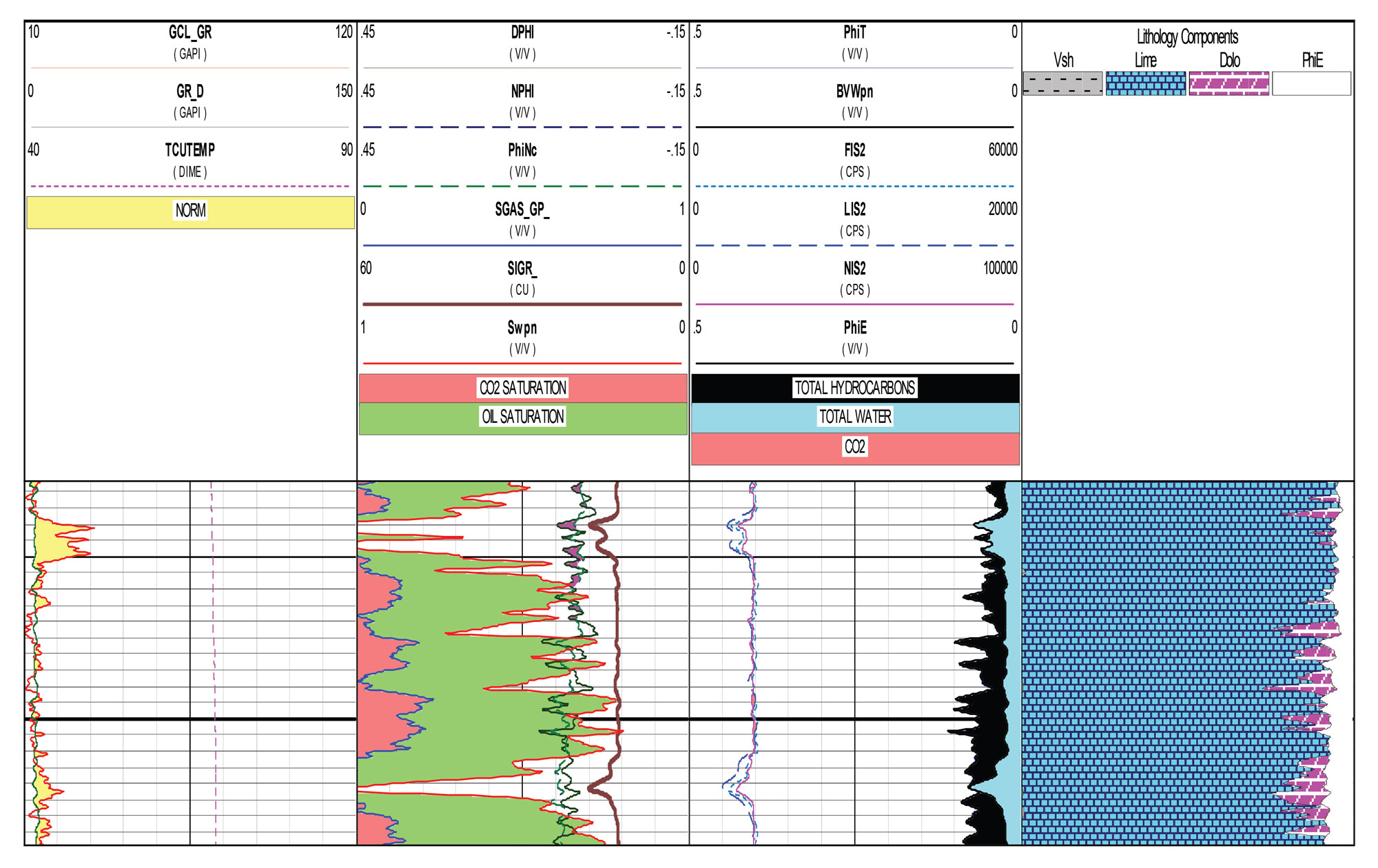

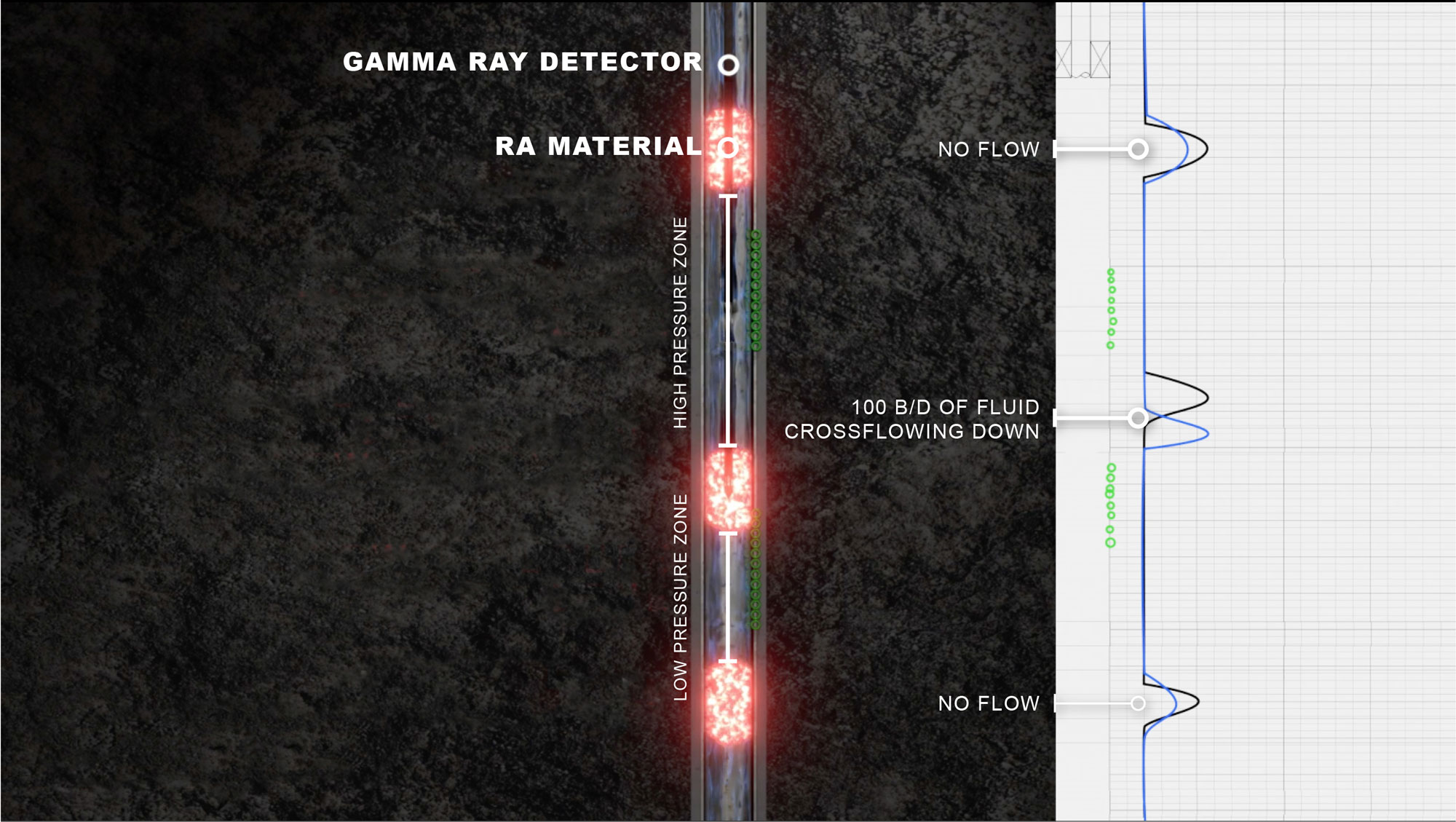

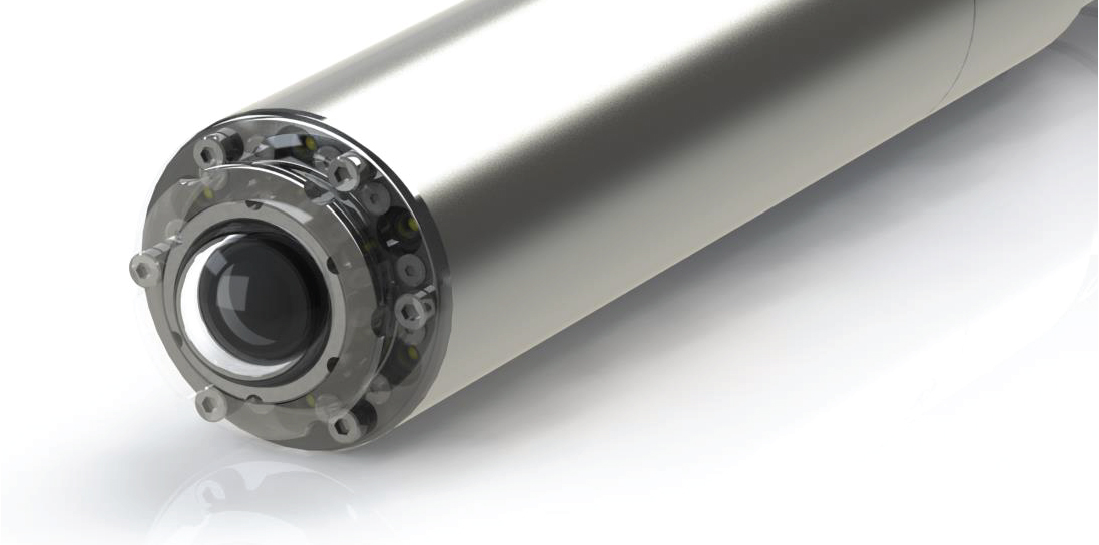

The NuWAV™ Downhole InSight™ camera provides quality, high-resolution video of the borehole environment, identifying problems such as a stuck object, a split within the casing, deviation and other features visible from inside the wellbore. This data helps engineers reduce drilling fluid losses, and make educated decisions about completions methods, retrieval of lost tools, and integrity issues with tubing and casing. The high-resolution NuWAV camera helps to mitigate the uncertainty of downhole operations and supports the operator’s formation evaluation program. Imaging systems from Renegade are a cost-effective and efficient method for gathering detailed downhole data.

By combining an ultra-sensitive image sensor with high-output lighting, the NuWAV camera provides a high-light output and can provide views of the most challenging environments. And unlike a standard image sensor that has a 4:3 or a 16:9 aspect rations, Renegade uses a sensor with a 1:1 ratio resulting in an impressive 180° field of view (FOV) in both vertical and horizontal directions.

This high-tech, versatile visualization system is designed to gather the maximum amount of borehole imaging data and is suitable for both conventional and deviated wells.

» Lightweight for easy transport and shipping.

Features

- Can be deployed over mono-conductor or multi-conductor wireline.

- Wide, 180° FOV in both vertical and horizontal directions.

- High light output means the camera can provide views in the most challenging environments.

- High-temperature rating of 257°F (125°C)

- High-resolution, high-definition and high-frame rate recording provides customers with a video of superior quality.

- Light weight for easy transport and shipment.

- Utilizes the latest optical sensor technologies to capture high-definition images.

THE DOWNHOLE INSIGHT™ NUWAV™ CAMERA IS ONLY AVAILABLE FROM RENEGADE SERVICES

Let’s start the conversation about how Renegade and NuWAV™ can work for you.

PERMIAN REGION

Sales: (432) 260-0029

Office: (432) 524-7239