» Our wellsite production logging supervisors have over 25 years’ experience running production logging services and can recommend the treatment options in case remedial operations are needed.

Production Logging Services

Critical Data to Help Maintain Well Performance

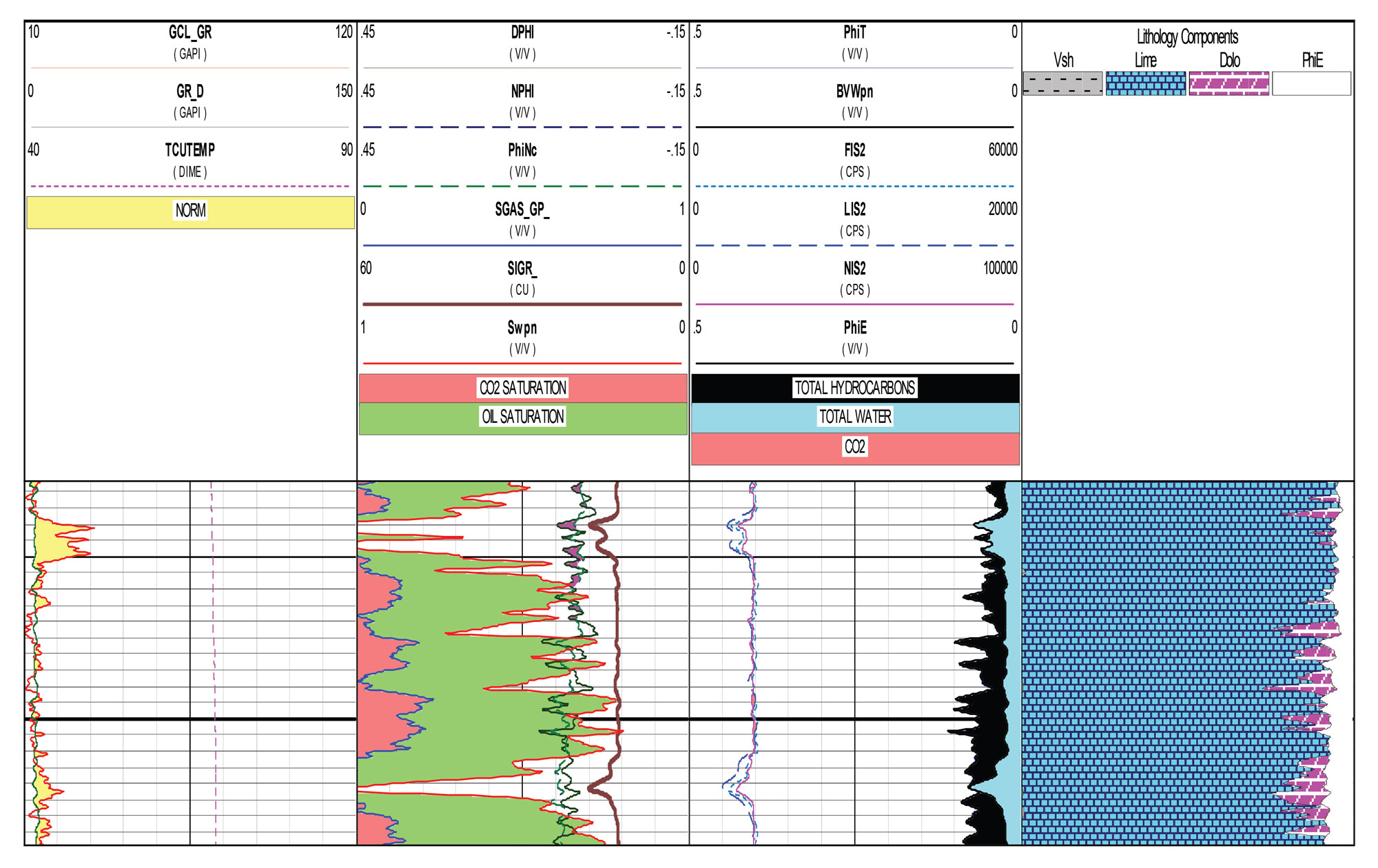

Production Logging services evaluate fluid production rate and flow in producing wells and are a main indicator of well performance and problem identification. The results of a production logging services help recommend remedial treatment or workover operations.

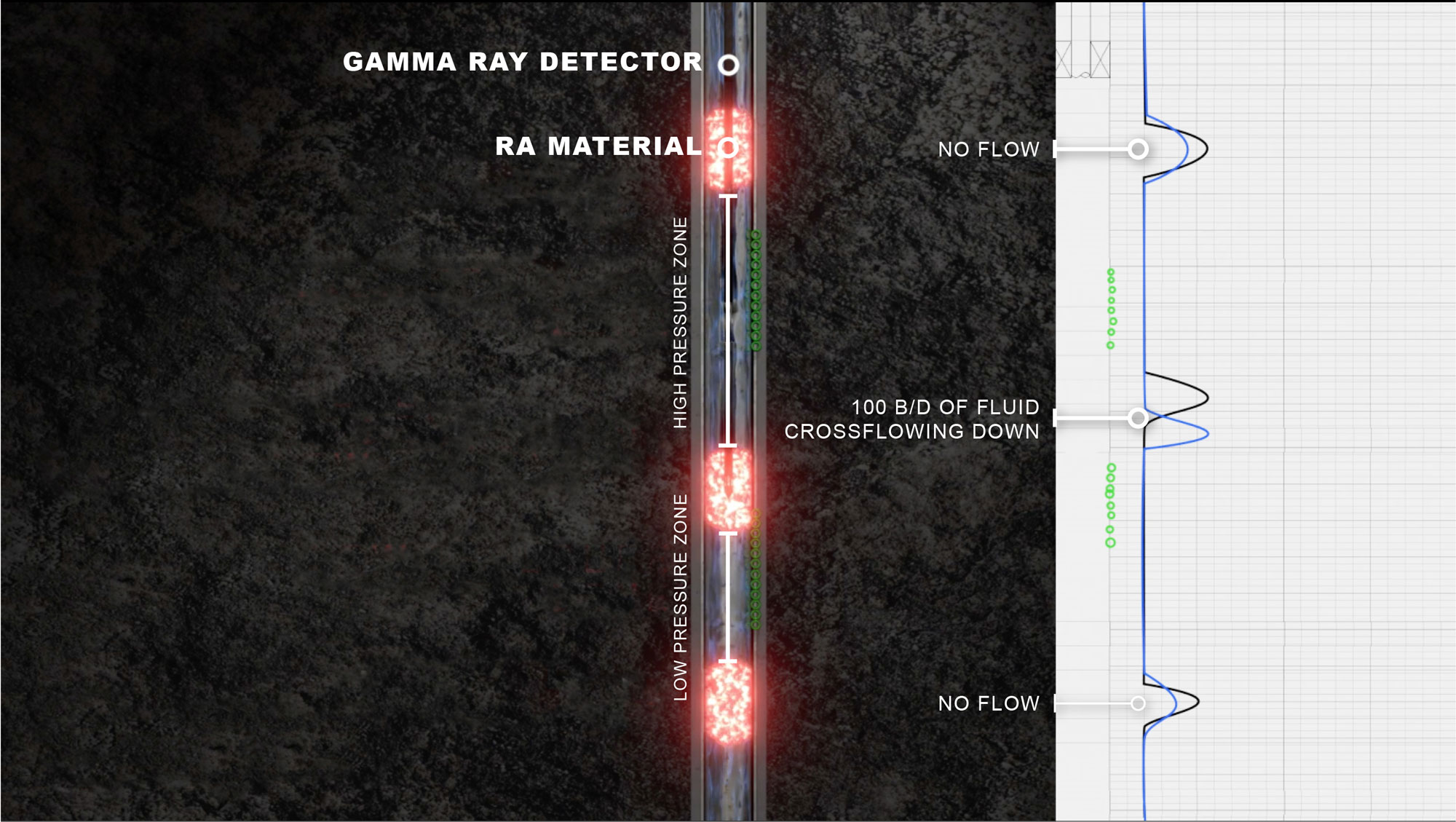

Renegade Production Profile Logging has proven to be the most reliable logging technique to give operators qualitative and quantitative evaluation of injection fluids and to aid in the evaluation of the performance of field floods.

The same technique can be reversed for producing wells. Radioactive tracer surveys ran in conjunction with other surveys, such as temperature gradient, capacitance, velocity, bottom-hole pressure, fluid density and calipers, will give the operator a full complement of surveying techniques to help fully evaluate their wells.

Applications

- Locate oil, gas and water entry

- Fluid flow: no-flow check and cross-flow check

- Shut-in cross-flow check

- Injection profile log: pump-in tracer, channel-down check and CO2 composite

» Renegade designs the optimum production logging job with the right tools and equipment.

While many companies may provide this service, only Renegade has the knowledge to perform a successful job every time.

Renegade Services has several production logging supervisors with over 25 years’ experience running production logging services. Our team will work with the operator to help ensure a safe, successful job, completed in the least amount of time.

- Select the right tools and equipment

- Make sure pressure control equipment is on location

- Review all well conditions such as temperature and pressure

- Weight bars and backup tools are available if needed

- Selection of radioactive isotope

- Safe operating procedures for handling and storage of radioactive materials

Step-Rate Tests

Obtaining data is the key to planning a successful frac job. Step-Rate tests are one method for estimating the maximum injection pressure, one of the most useful parameters when planning the optimum frac treatment.

A step rate test can accurately measure the injection pressure needed to fracture a formation when planning a hydraulic frac job. During the test, fluid is injected into the formation at increasing pump rates. As each rate stabilizes, injection pressure data is taken for each rate. The resulting data is used to create a plot displaying injection pressure verse injection rate. From this plot, pressure and flow rates can be established to identify the fracture pressure necessary to fracture the formation and successfully place fluid and proppant.

Spectral Noise/Digital Temperature Survey

The relationship between reservoir flow and wellbore flow is critical to well performance. The Renegade spectral noise log in conjunction with a high-precision digital temperature survey can accurately locate and quantify reservoir flow and wellbore flow to help determine the relation between the two.

This combination can diagnose unexpected well problems and also proactively ensure the well is working properly. Resulting data provides a wealth of information on well performance and can help identify zones where remediation is needed.

- Identify surface casing vent flow (SCVF)

- Identify external gas migration (GM)

- Identify fluid flow behind multiple casing pipe barriers

- Locate source of downhole leaks

- Help identify leaking fluids into freshwater reservoirs

- Identify regional lateral flows and crossflows

- Differentiate fluid and gas flow and amount

- Identify annulus leaks for sealing with Renegade Local Expander technology so P&A can commence

Renegade can use bond logs and casing inspection logs to identify, map and further explain spectral noise/digital temperature survey data.

Renegade Memory Gauges

A producing wellbore creates a tremendous amount of information that must be gathered, managed and then interpreted. A variety of diagnostic tools can help you manage the production of your well and gain valuable insights into the processes that are occurring downhole. These tools provide the data that help operators to identify what systems to use to increase or maintain production and how to adapt to changing conditions of the wellbore.

Memory gauges are one of the most helpful tools for well diagnostics. They detect and measure temperature and pressure at points along the wellbore. These gauges are beneficial because they provide downhole information without requiring substantial resources.

They also eliminate the need for deploying e-line each time temperature and pressure measurements are required. Memory gauges are powered by a battery pack and can be set downhole and left for an extended period to capture and store data and then be retrieved at a later date.

- Data can be used to determine the flow rate of the well

- Provide information to help implement the right lift systems to maintain production

- Help devise a cost-effective and timely program to monitor and maintain the well production

Maximize Your Well Performance with Renegade's Reliable Production Profile Logging

Call us today to get started.

WEST TEXAS

Sales: (806) 215-4111

Office: (806) 897-0735

OTHER LOCATIONS

Sales: (806) 787-9725

Office: (806) 897-0735