» The Circulating Pyro Torch delivers consistent and proven results when adequate annulus flow is required for a successful cutting job.

» The Circulating Pyro Torch delivers consistent and proven results when adequate annulus flow is required for a successful cutting job.

Circulating Pyro Torch

Effective operations when annular flow is required for the Radial Cutting Torch

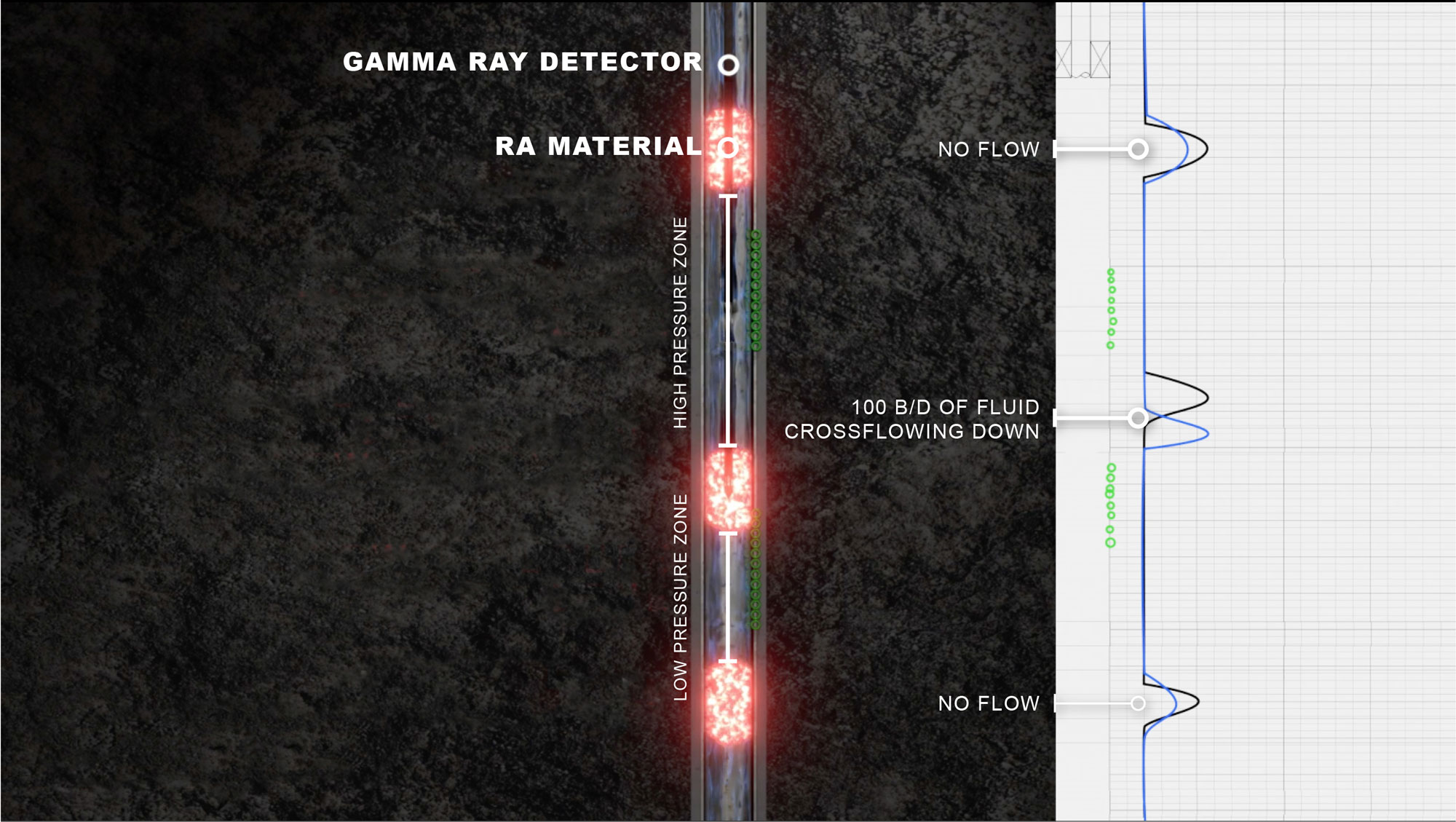

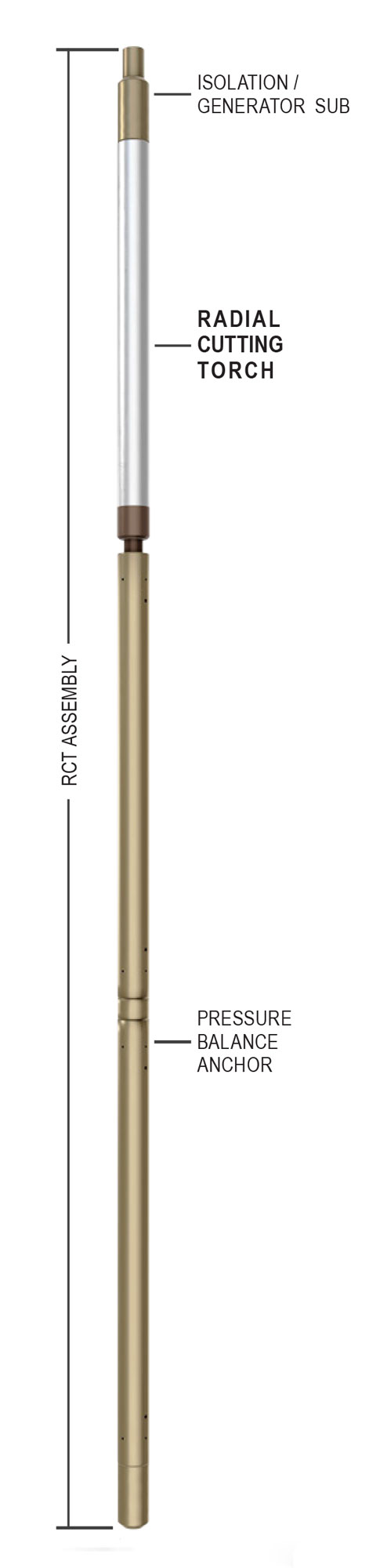

MCR Oil Tool’s circulating pyro torch was developed using the same principles as the successful and field-proven radial cutting torch (RCT) system. However, in some conditions, adequate flow into the annulus is required when executing a successful RCT job. Explosive perforators and punchers are not reliable at producing consistent holes that provide sufficient flow, having a dramatic effect on success when cutting with the RCT. The circulating pyro torch delivers the required annular flow prior to cutting and provides a consistent and reliable punch in coil tubing, casing, and drill pipe. By utilizing the latest in MCR’s proprietary non-explosive, non-hazmat rated fuel technology, you can complete your job faster and safer than ever before.

- Non-explosive

- Non-hazmat rated fuel

- Radio safe

- Operates in temperatures up to 500°F (260°C) and pressures up to 25,000 psi (172.4 MPa)

- Perforates all steel, high chrome, and plastic-coated tubulars

- Perforates in exotic fluids or dry pipe

- Single/dual perforations in sizes from 0.38 in 2 to 7.0 in 2

- Deployable within hours and not days

- Minimizes downtime and associated costs

Operation

All Renegade operators are trained and certified by MCR for proper tool operation for safe and efficient operations.

MCR’s circulating pyro torch assembly is lowered into the well to the desired depth. MCR’s thermal generator ignites and activates the primary fuel load causing an increase in internal pressure. Following internal pressure rise, plasma exits the torch which perforates the target pipe. By design, the CPT cutting jet forces the tool against the wall of the pipe; the high frictional forces between the CPT and the wall of the pipe are greater than the thrust forces exerted by the pressure bubble, stabilizing the perforator to make the cut. It is this feature that allows MCR’s perforators to function properly in plugged pipe situations.

- Undersized for restrictions

- HPHT environments

- Custom tools available

Support Tools

Generator Safety Sleeve® (GSS)

- Safely dissipates all thermal generator energy in the event of operator activation error on surface

Remote Firing Mechanism® (RFM)

- Data logging tool and firing system

- Safely enables all MCR cutting systems

Faster and Safer Results with MCR’s Circulating Pyro Torch

The service company that you hire matters – Call us today to work with us.

WEST TEXAS

Sales: (806) 215-4111

Office: (806) 897-0735

OTHER LOCATIONS

Sales: (806) 787-9725

Office: (806) 897-0735