Case Study

The Renegade Local Expander Tool eliminates annular gas flow that has hindered operations for over four years.

EXPANDABLE TECHNOLOGY SOLVES PROBLEM IN HOURS

Annular Gas leaks originating from sub surface cementing problems continue to be a monumental problem for operators worldwide. New technology has now been proven on hundreds of wells in multiple countries to successfully and permanently seal and correct the micro annular leaks and stop gas flows to surface. The below case history and accompanying VIDEO illustrate one challenge faced by an operator and the innovative technology that successfully solved the problem.

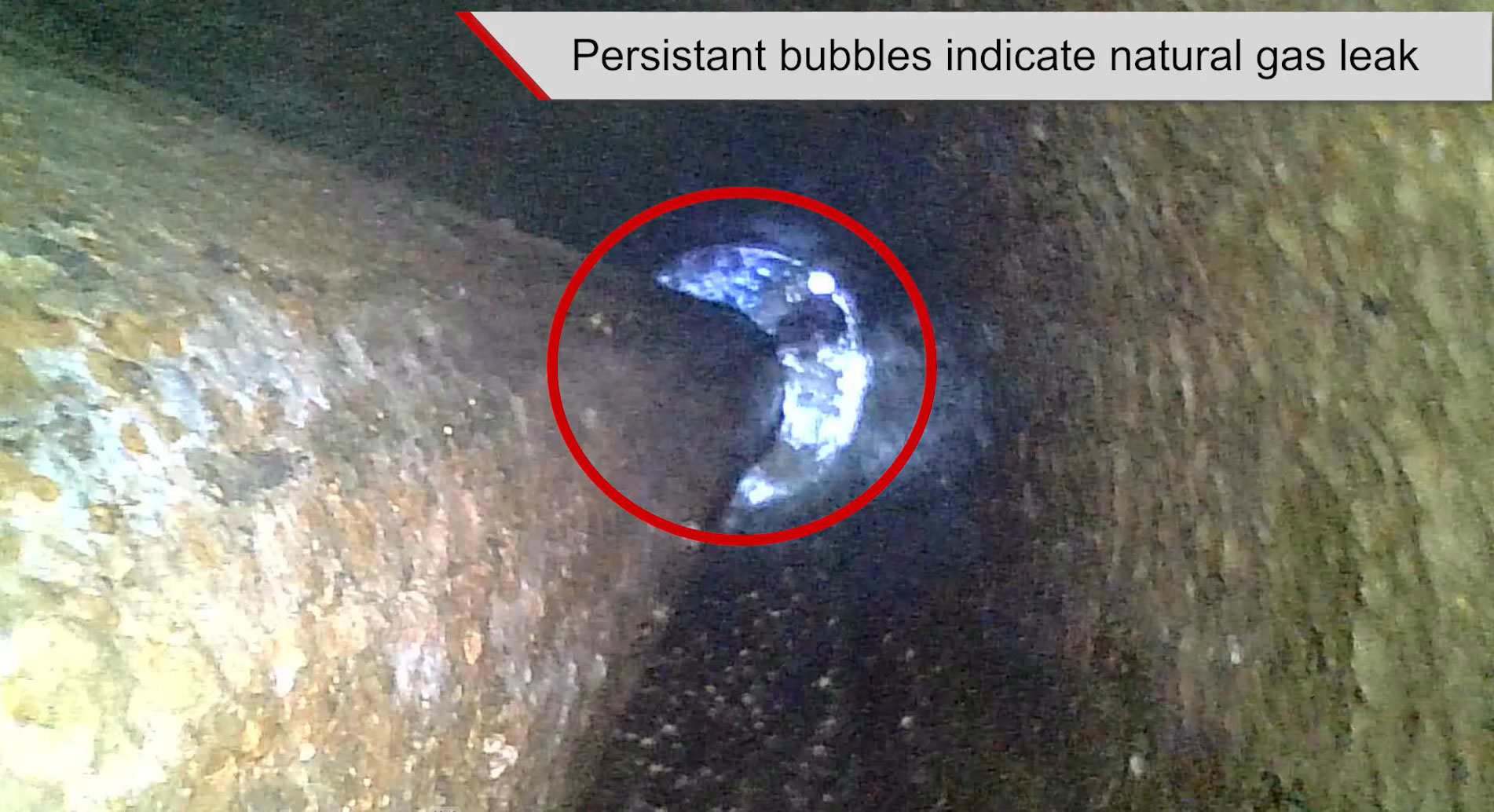

A breech in the 9-5/8-in. casing caused an annular leak that allowed gas to flow into this well located in the Marcellus Shale in the U.S. The well included a 16,000 ft lateral section and the annulus to be isolated was 5-1/2-in. The 5-1/2-in. casing was cut close to surface leaving a stub that presented the opportunity to view the annular gas leak in a novel perspective. A small downhole camera captured the gas flow, indicated by persistent natural gas bubbles entering the well through leaks in the annular cemented casing. This problem had been challenging this operator for over four years!

After quickly evaluating the problem and reviewing well details, Renegade presented the following solution utilizing the Local Expander™ Annular Squeeze Tool: 18 casing expansions in six sequences within the vertical shallow section of the 5.5-in. casing were made to completely isolate the 9-5/8-in. by 5-1/2-in. annulus.

The results were immediate, with 80 to 90 percent of the gas flow cut after the first set of expansions were completed. After applying three additional expansion sequences, the gas leak was shut off 100 percent. The total job was completed in a six hour intervention.

The Renegade Local Expander has been successfully used to seal annular gas flow on over 320 well interventions in the U.S., Canada and around the world. This technology stops the flow from behind the casing and the resulting harmful emissions from reaching the atmosphere. The result is a permanent well repair that does not affect casing integrity. Contact Renegade today at [email protected] to find out more about this proven technology.

Local Expander – Annular Squeeze Tool™

Let's start the conversation about how Renegade and the Local Expander can work for you.

RENTALS

Technical: (337) 371-7635

Sales: (325) 267-1693

Office: (337) 321-4145

SERVICE

Sales: (318) 272-8320

Office: (337) 321-4145