COMMITTED TO QUALITY – DEDICATED TO SERVICE

Renegade Wireline Services is a complete oilfield service provider with solutions that aid in every stage of completions and production, from Exploration to Plug & Abandon.

PRODUCT & SERVICE HIGHLIGHTS

Renegade Honors Gunset Legacy of Success in Snyder by Prioritizing Employees

Pictured (l-r) are Gary Gunset, Judy Atkins, Brett Douglas, JP Smith, Chuck Barbee, Joe Stewart, Tommy Davis, Adam Webster, Drew Bane, Keith Manlief, Amanda Steelman, Mariah Carrasco and Kylee Gunset.Renegade Honors Gunset Legacy of Success in...

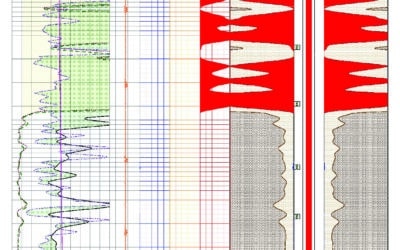

Case Study: Perf Cluster

Case Study: Analyzing Radioactive Tracer Stimulation Data to Determine Frac STage PerformanceTo provide well performance data to a Permian Basin operator, Renegade conducted a radioactive tracer analysis on Stages 1 through 6 at depths ranging from...

Celebrating a Remarkable Career

Celebrating a remarkable career Honoring Scott Wruck's Impact and Celebrating His RetirementEffective January 5th, 2024, we bid farewell to an industry veteran and an invaluable member of our community in NEPA, Scott Wruck. His impressive 45-year...

SAFETY

OUR COMMITMENT TO SAFETY

Renegade Wireline Services is so committed to making operations safer that we created a safety training service company and were key players in the creation of RigLock®, FRACLOCK™, Gunhandler™, and various other HSE innovations which protect wireline operators and all others on the pad. Renegade utilizes digital safety tracking

We are members of: Avetta, PEC Safety, and ISNetworld.

The safety and health of our employees is the first consideration in operating this business. Without question, it is every employee’s responsibility and prerogative at all levels. Every Renegade employee is trained and empowered by management and executives to follow safety standards with intentional diligence.

Our base safety policy is as follows:

It is the intent of this company to comply with all laws. To do this we must constantly be aware of conditions in all work areas that can produce injuries. No employee is required to work at a job they know is not safe or healthful. Your cooperation in detecting hazards and, in turn, controlling them, is a condition of your employment. Inform your supervisor immediately of any situation beyond your ability to authority to correct.

Prevention of occupationally-induced injuries and illnesses is of such consequences that it will be given precedence over operating productivity, whenever necessary. To the greatest degree possible, management will provide all mechanical and physical activities required for personal safety and health, in keeping with the highest standards.

We will maintain an occupational safety and health program conforming to the best practices of organizations of this type. To be successful, such a program must embody proper attitudes towards injury and illness prevention on the part of supervisors and employees. It also requires cooperation in all safety and health matters, not only between supervisor and employee, but also between each employee and their co-workers.

Our objective is a safety and health program that will reduce the number of injuries and illnesses to an absolute minimum, not merely in keeping with, but surpassing the best experience of operations similar to ours. Our goal is zero accidents and injuries.

The Renegade Wireline Services Difference

SIMPLE ALL-INCLUSIVE PRICING PLANS

Our prices are competitive and in line with industry standards. With no surprise fees and straight forward billing, you can rest assured that there’s no need to shop around. You’ll find that we’re pretty easy to work with too.

RENEGADE ON SITE IN 24 HOURS OR LESS

Our experienced wireline operators can be on your site within 24 hours (for any location within 500 miles of one of our district offices). We are located in all the major plays in the United States.

BIG CAPABILITY WITH GREAT CUSTOMER SERVICE

We are a large company with advanced technology but we react to the needs of our customer and the market like a small company; response times, customer focus, genuine team effort.

EXCLUSIVE, GROUND-BREAKING TECHNOLOGY

From the beginning, we have invested time and capital into the development of better, smarter tools to solve problems for our customers and have consistently been early adopters of industry innovations. Greaseless line, Gunhandler, Local Expander™, RigLock and many more.

Ready to Experience the Renegade Difference?

Speak to someone right now at: (806) 894-6088, or fill out the form below and we will be in touch shortly.