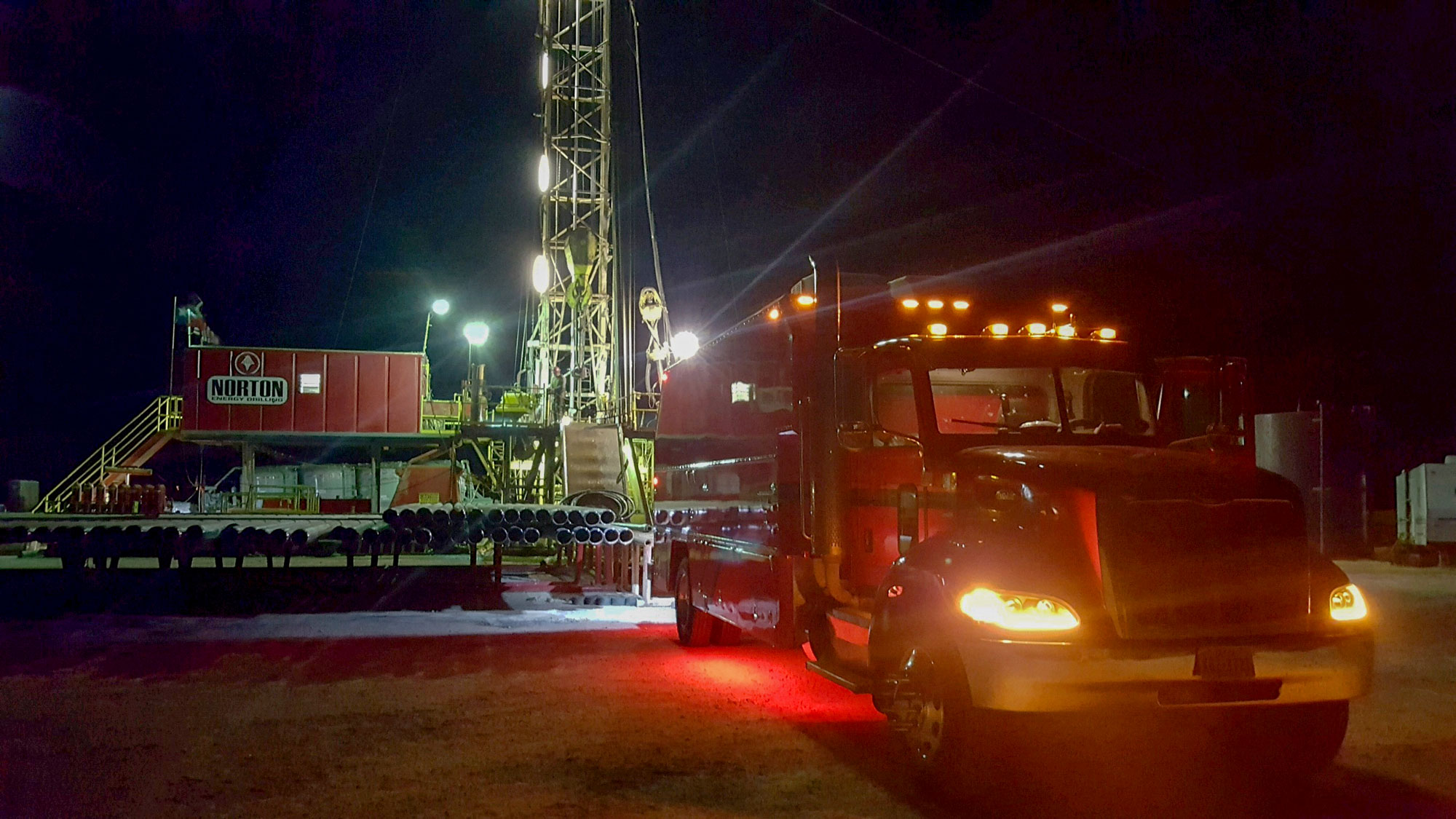

» Renegade Slickline Unit

COMPLETE CONVEYANCE SYSTEMS FROM RENEGADE

SLICKLINE, BRAIDED LINE AND ELINE SERVICES FOR ANY APPLICATION

Once a well is producing, certain practices must be performed to maintain production in addition to identifying and correcting problems that can impede production. Selecting the right process and executing correctly, selecting the best equipment, and experienced wellsite personnel can all make a huge difference in the cost and time of a project. Selecting the conveyance method to deploy these operations is one example.

- Renegade crews are trained to run the full range of services, regardless of the conveyance method. We make sure our crews are cross-trained with experience on both slickline units and eLine units. Most of our crews have 10+ years’ experience.

- Sour line services available for work in H2S and CO2 environments

- Greaseless line for environmentally-friendly, pump-down operations

- Special units available with reels containing both braided and slickline

- Renegade has experience running all types of line — slickline, braided, eLine or a combination, since 2009

Renegade offers slickline, braided line, eLine or a combination of these options for any wellsite application.

SLICKLINE OPERATIONS

Slickline is a non-conductor, single-strand wire used to perform many different remedial and mechanical services on producing wells. It is made of mild steel, ranging in diameter from 0.072 in. to greater than 0.125 in. These tools are generally used for setting plugs, running memory gauges and other mechanical services. Slickline is a small line that packs a big punch. It is strong and durable and can be run rapidly in and out of a wellbore allowing operators to quickly collect valuable well data.

BRAIDED LINE OPERATIONS

Braided line is a non-conductive, twisted braid of multiple steel wires. Braided line is strong and durable and useful in numerous applications such as fishing operations and swabbing fluid from a well. In a producing well, the hydrostatic pressure sometimes overcomes the formation pressure, causing well fluid to slow. The result: decreased overall production from the well. Braided wire is capable of quickly removing the overburden of fluid in the well to help resume production.

ELINE OPERATIONS

Some areas use single-conductor electric wireline, known as small line or eLine, for traditional slickline service. Eline adds a level of versatility not found in slickline or braided line. Renegade Services uses an electric line to provide the most accurate data-gathering capabilities possible. The insulated cable is surrounded by multiple strands of wire called armors. This conductive wire allows electrical signals to be sent downhole to initiate tool activities and retrieve well data in real time.

» Renegade offers several conveyance options for wellsite applications.

DETERMINING THE BEST CONVEYANCE METHOD FOR WELLSITE EFFICIENCY

In certain situations, it may be more cost-effective to run standard mechanical services on eLine. Renegade can perform all traditional mechanical services such as tubing perforating and circulation in hole, on eLine. However, with eLine, we can also perform services such as logging, perforating and tracer services without having to get another truck on location. One call gets you anything that you will need for most conventional services. Renegade currently offers 7/32-inch (0.2188-inch) diameter eLine.

To run these services, Renegade utilizes a large, 5.5-inch lubricator. Mast units are run through a three-stage grease head with grease onboard for pressure work. This provides additional levels of safety and pressure control for pressure work.

- Tubing perforating

- Circulating in hole

- Radioactive tracer services

- Radial cement bond log

- Casing inspection

- Compensated neutron log

- Any traditional logging service with larger 5.5-inch lubricator

Renegade offers slickline, braided line, eLine or a combination of these options for any wellsite application. Our crews are trained to run the full range of services, regardless of the conveyance method and have the experience to help select the best and most cost-effective method for your well. We also have sour line services for H2S and CO2 environments and greaseless line for environmentally-friendly, pump-down operations. Click here to learn more about Renegade’s full line of conveyance systems.

Renegade Wireline Services is the largest independent provider of cased-hole electric wireline services and is recognized as the premier horizontal cased-hole completions service provider in the North American oil and gas industry. Renegade offers professional, experienced personnel with a cased-hole and radioactive tagging focus working in an efficient and safe manner to produce operational excellence and customer satisfaction.

Conveyance Solutions from Renegade for Every Application

24/7 on-call service from the largest and most diverse independently owned wireline company in the US.

PERMIAN REGION

Sales: (325) 207-0779

Office: (325) 573-4441

NORTHERN REGION

Sales: (412) 427-3779

Office: (724) 925-2900

GULF/MIDCON REGION

Sales: (318) 278-5480

Office: (601) 649-2890