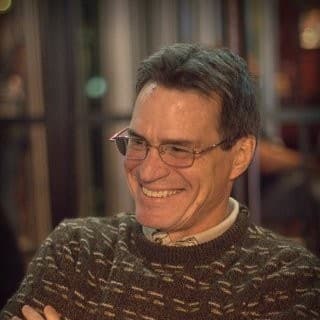

Celebrating a Remarkable Career – Scott Wruck

» Scott Wruck

Celebrating a Remarkable Career

Honoring Scott Wruck’s Impact and Celebrating His Retirement

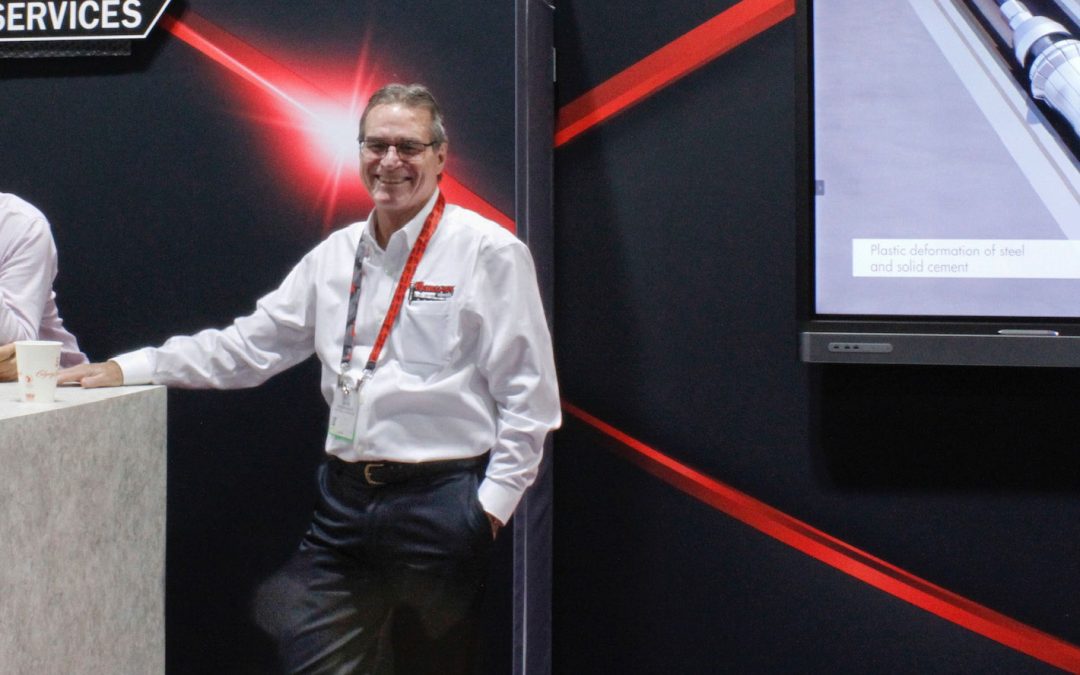

Effective January 5th, 2024, we bid farewell to an industry veteran and an invaluable member of our community in NEPA, Scott Wruck. His impressive 45-year career in the oil and gas industry stared in WV working for NL McCullough (6 years). Next he made a move to Halliburton where he served for 16 years in Corpus Christi and 14 years in California as an in-house rep for Oxy and Chevron. As for the last 8 year of his career, Scott spent those with us at Renegade. Scott is ready to embark on a well-deserved retirement.

“The last 8 years I have been working with Renegade Services which has been a true blessing … each step of my career there has been so many people, both internally and with my client base, that has been key to long and successful career. I truly thank all of you.”

Scott has been an integral part of our company and the NEPA community, leaving an indelible mark on both. His wealth of knowledge, expertise, and commitment to excellence have been instrumental in driving our success. Scott’s unparalleled work ethic, leadership, and genuine care for those around him have set a benchmark that inspires us all.

As we bid farewell to Scott, we celebrate his remarkable career and the impact he has made. We are excited to see him embrace this new chapter and enjoy the fruits of his labor. Retirement is a time to reflect, relax, and relish in the accomplishments achieved throughout one’s career. We have no doubt that Scott will thrive in this next phase of his life, bringing the same passion and enthusiasm that characterized his time at Renegade.

On behalf of the entire Renegade family, we thank you, Scott, for your unwavering commitment, your invaluable contributions, and the impact you have made on our company and community. Your presence will be missed, but your legacy will endure.