Free Point/Backoff Operations

» Renegade’s Free Point/Backoff service can quickly determine the stuck point, then free and recover the stuck tool string or pipe.

Free Point/Backoff Operations

Renegade has the equipment and knowledge to quickly free stuck pipe or tools

When pipe or tools become stuck in the well, it can quickly become one of the costliest challenges an operator is faced with. Until the problem is resolved, other issues including delayed drilling, increased NPT and additional expenses for equipment and crew become critical. When this problem occurs, you need a company that provides fast response, safe operations and a knowledgeable crew with the best equipment.

Quickly determining the stuck point, loosening or severing the stuck string and then recovering as much of the stuck tool or string as possible is imperative to get wellsite operations going again. Renegade has the equipment, personnel and experience to provide the solution when your toolstring or pipe becomes stuck.

For successful pipe recovery and stuck tool operations you must first determine the free point of the tool or pipe. The free point is the depth at which the tubing, casing or tool that is stuck in the borehole is free to move. This will be the point at which recovery operations can begin.

Renegade’s free point tool provides vital information that aids in cutter type selection and helps identify the location to separate pipe. Always ran with a CCL, the free point tool is first positioned at a known free spot to set up the tool and check proper tool functionality.

A sensor picks up movement in the assembly associated with tension, compression or torque. This signal is sent to a surface free point panel for display and recording. Renegade specialists continue the process until zero movement is detected by the sensors.

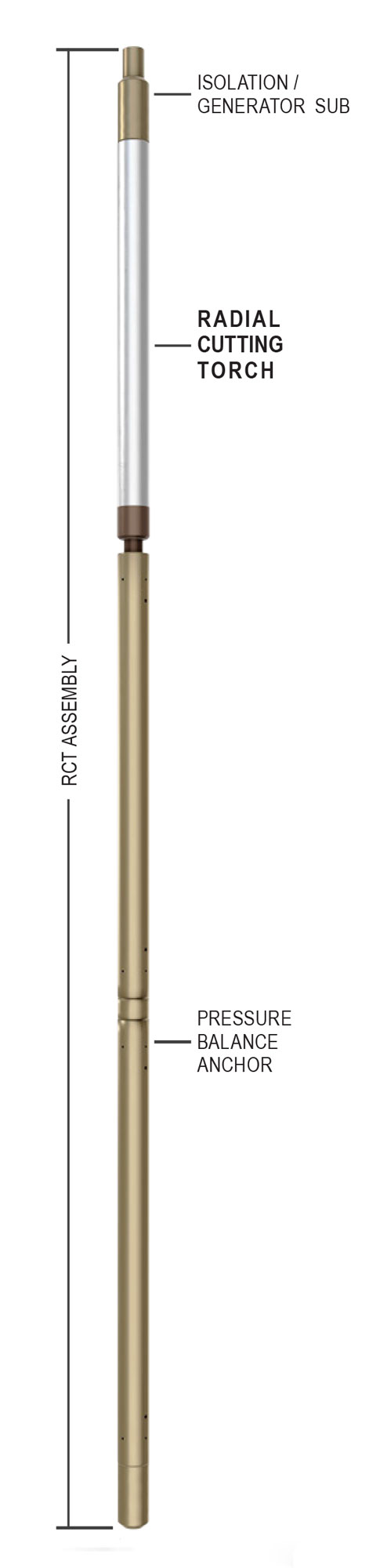

Next the connection or pipe must be severed to pull the remaining string out of the hole. This can be accomplished by applying a ‘back off’ or reverse torque and at the same time detonating an explosive charge inside the nearest string connection.