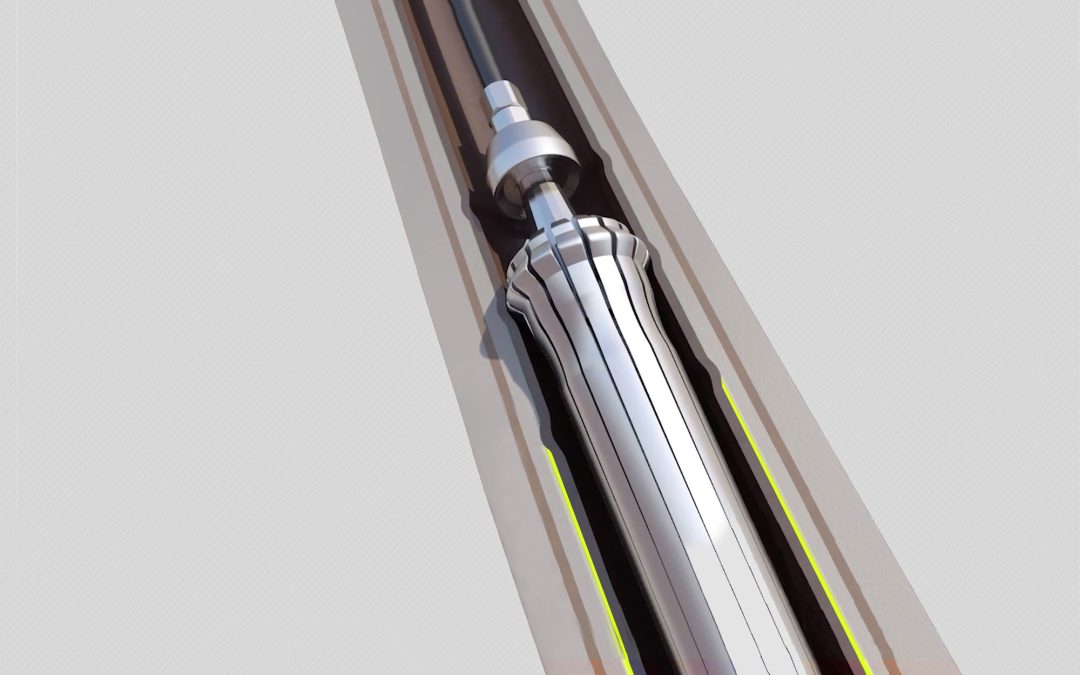

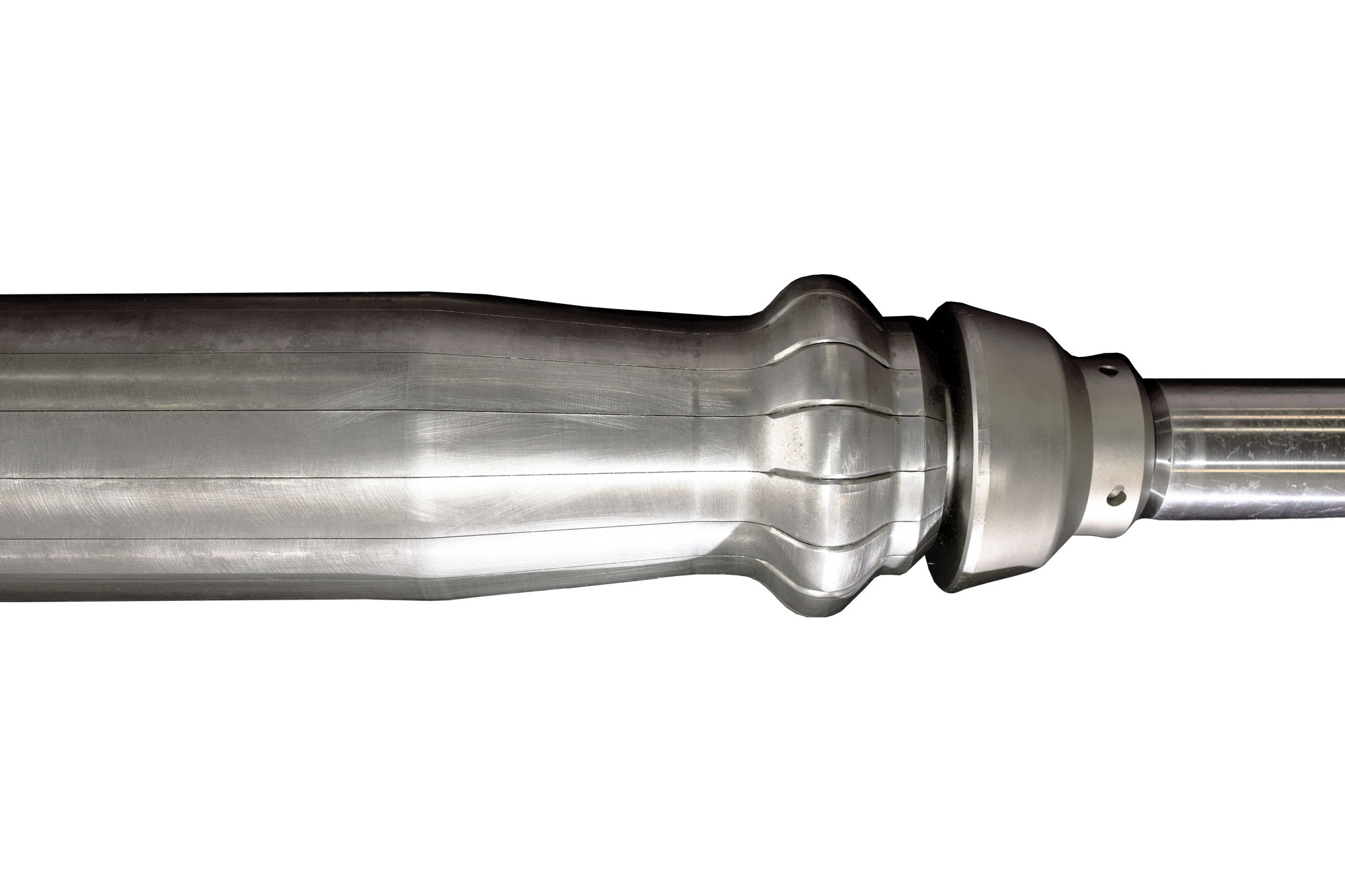

LOCAL EXPANSION IS A SIMPLE WAY TO SEAL MICRO-ANNULI AND STOP UNWANTED GAS FLOW. THIS ONE-RUN TOOL LEVERAGES A TELESCOPING CONE THAT EXPANDS A RADIAL SET OF HARDENED KNUCKLE-BENT FINGERS INTO THE CASING.

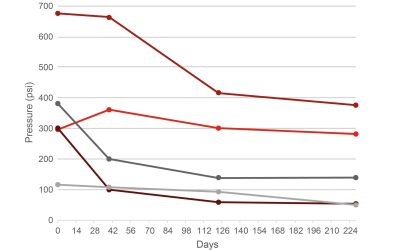

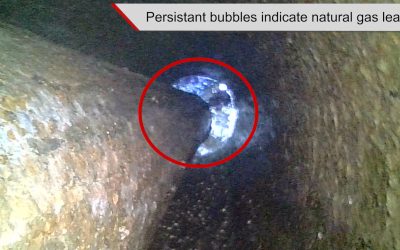

This new process involves a retractable, expandable mechanical device that induces plastic deformation and elongation of the inner diameter of the casing string. The result is the outer diameter of the casing expanding into the cement. The associated volume reduction in the annulus closes micro-annuli defects in the cement and results in an overall densification of the cement. This alternative offers rigless remediation of annular gas/fluid migration and bradenhead pressure.

This new process involves imposing permanent deformation on the casing pipe to locally enlarge its diameter. It operates in a mechanical, fully controlled manner and can be quickly repeated at any target interval for engineered redundancy to fully eliminate all micro-annuli and backside gas flow problems with confidence.

HOW IT WORKS

THE LOCAL EXPANDER™ APPLIES AN ACTUAL SQUEEZE TO THE EXISTING CEMENT BY EXPANDING THE CASING INTERNALLY.

- Fingers at the top end of the tool are pressed outward by an actuated cone.

- The fingers expand the casing into the cement.

- RESULT: The cement is locally densified. The source of the bradenhead pressure path is eliminated.

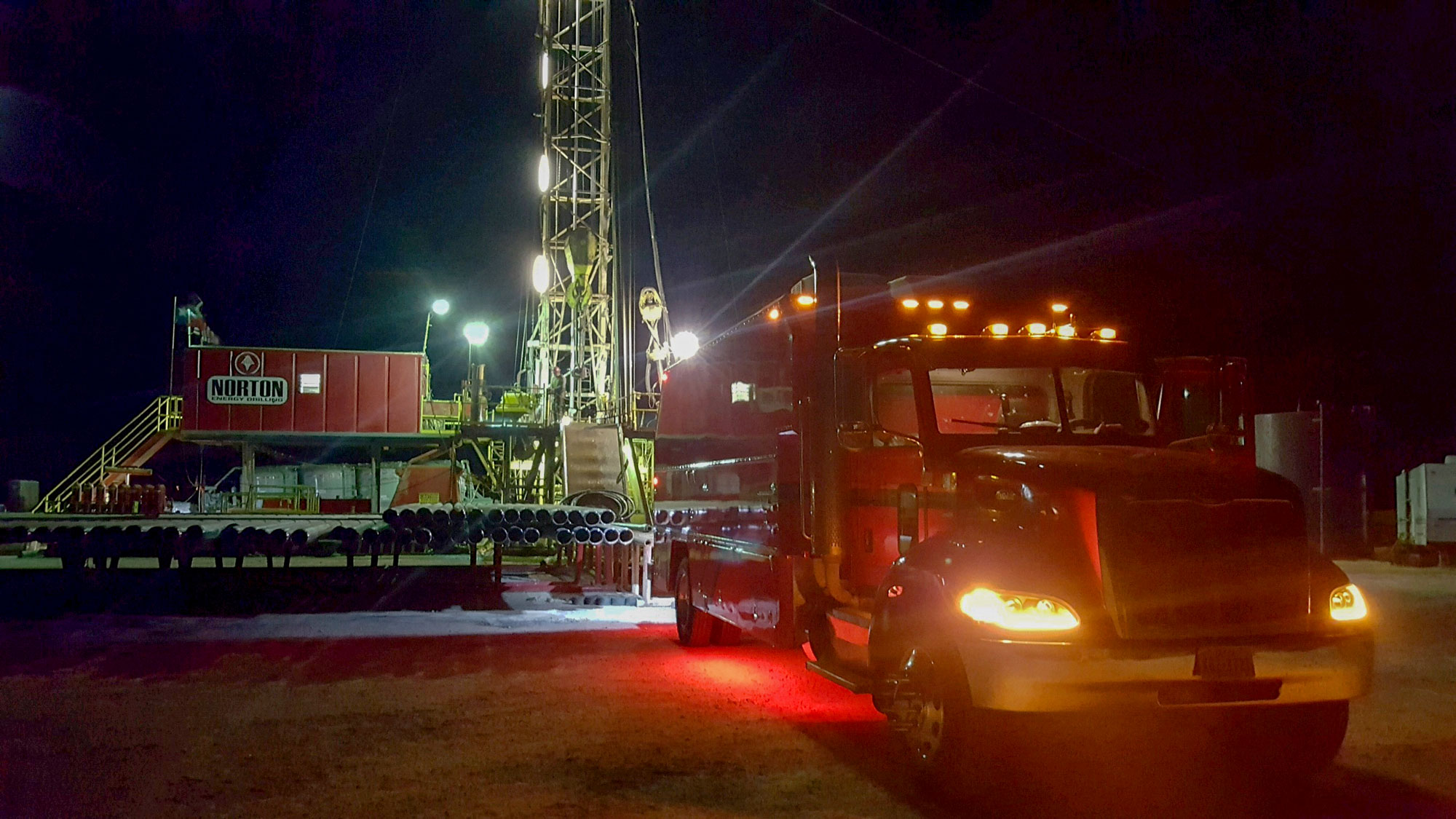

CONVEYED VIA ELECTRIC WIRELINE

The tool creates a series of crimps in the casing that eliminate the micro-annulus. By using an electric line and having a one-run tool, the Local Expander has achieved the same results as a conventional squeeze but at a fraction of the cost and effort.

SAFETY

Safety concern for workover operations is also significantly minimized with the implementation of the Local Expander. Crimping casing close to the surface allows crews to work under much safer conditions knowing there is no gas seepage to the surface.

PLUG AND ABANDON

Wells scheduled to be permanently taken out of service must be totally sealed not only at the surface but throughout the casing string. This means no leaks of any kind. This often results in a backlog of wells waiting for P&A. The Local Expander is the trusted choice for scheduled P&A because it can affordably seal any leaks prior to P&A. Once gas migration leaks are sealed, plug and abandonment can proceed.

In addition to plug and abandonment, several other wellsite operations can utilize the benefits of the Local Expander.

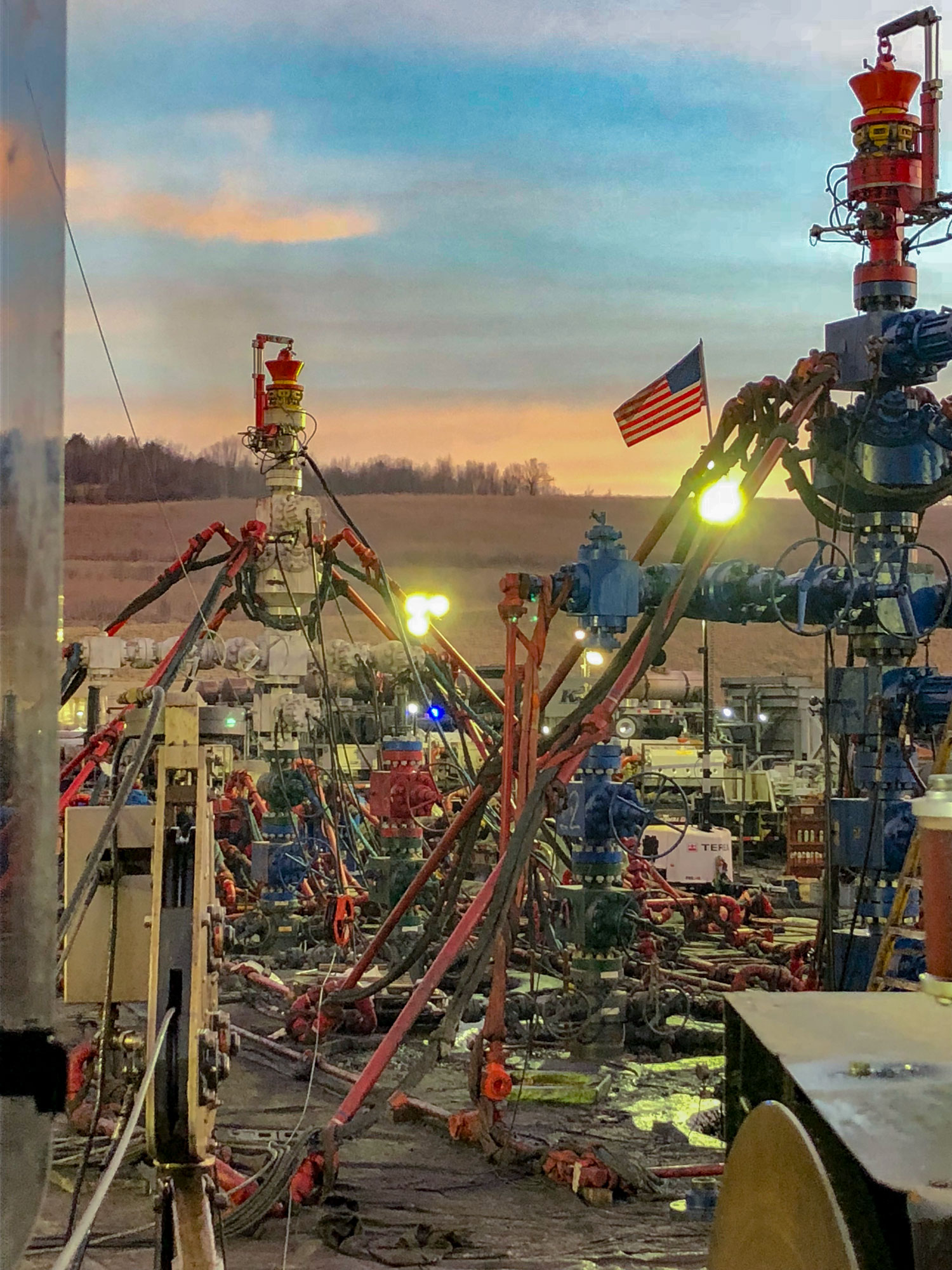

- Shutting off backside pressure in producing or injection wells

- Stopping gas migration behind the surface and/or intermediate casing strings during the drilling process

- Preventative maintenance prior to hydraulic fracturing where the Local Expander is used to isolate the frac zone

- Create a barrier during squeeze cementing

REGULATORY

The Local Expander is the preferred solution for regulatory departments because it repairs micro annulus without the use of chemicals and perforation. Pennsylvania DEP and Colorado’s Oil & Gas Commission are two of several agencies advocating the importance of eliminating gas migration from the wellbore.

ENVIRONMENTAL

Because there are no permanently deployable tools, products, or chemicals, the Local Expander leads the industry as an alternative service that leaves no trace beyond the intended service. Keeping unwanted gases and liquids in the ground instead of permeating to the surface on the backside of casing is the challenge that Local Expander effectively solves.