RENEGADE ESOP – Renegade Wireline Sercives recently announced the implementation of an employee stock ownership plan. Employees are automatically enrolled in the pland and become vested after three years of service. They are also eligible for funds at retirement age, 65. Pictured are Renegade board member, from left to right: Founders Matt Gray and Randy Cassady; Steve Gray and David Gray. (Photo courtesy of Renegade Wireline Services)

A business is not defined by the product or services it provides but by the people who make it all possible.

Renegade has taken a leap towards showing its customers and most importantly, its employees, that the

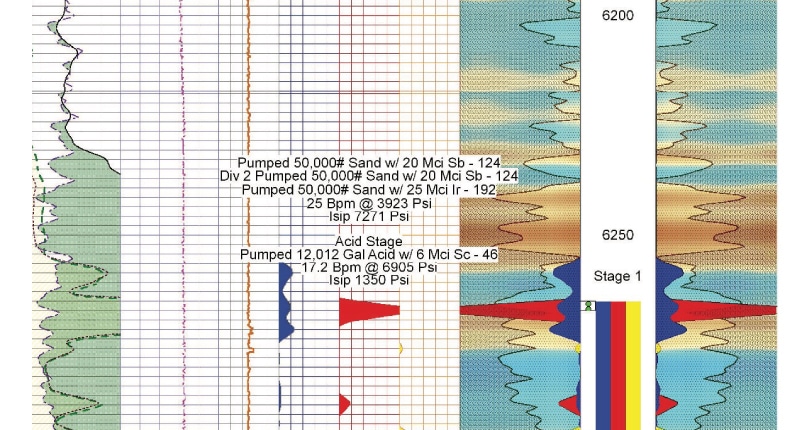

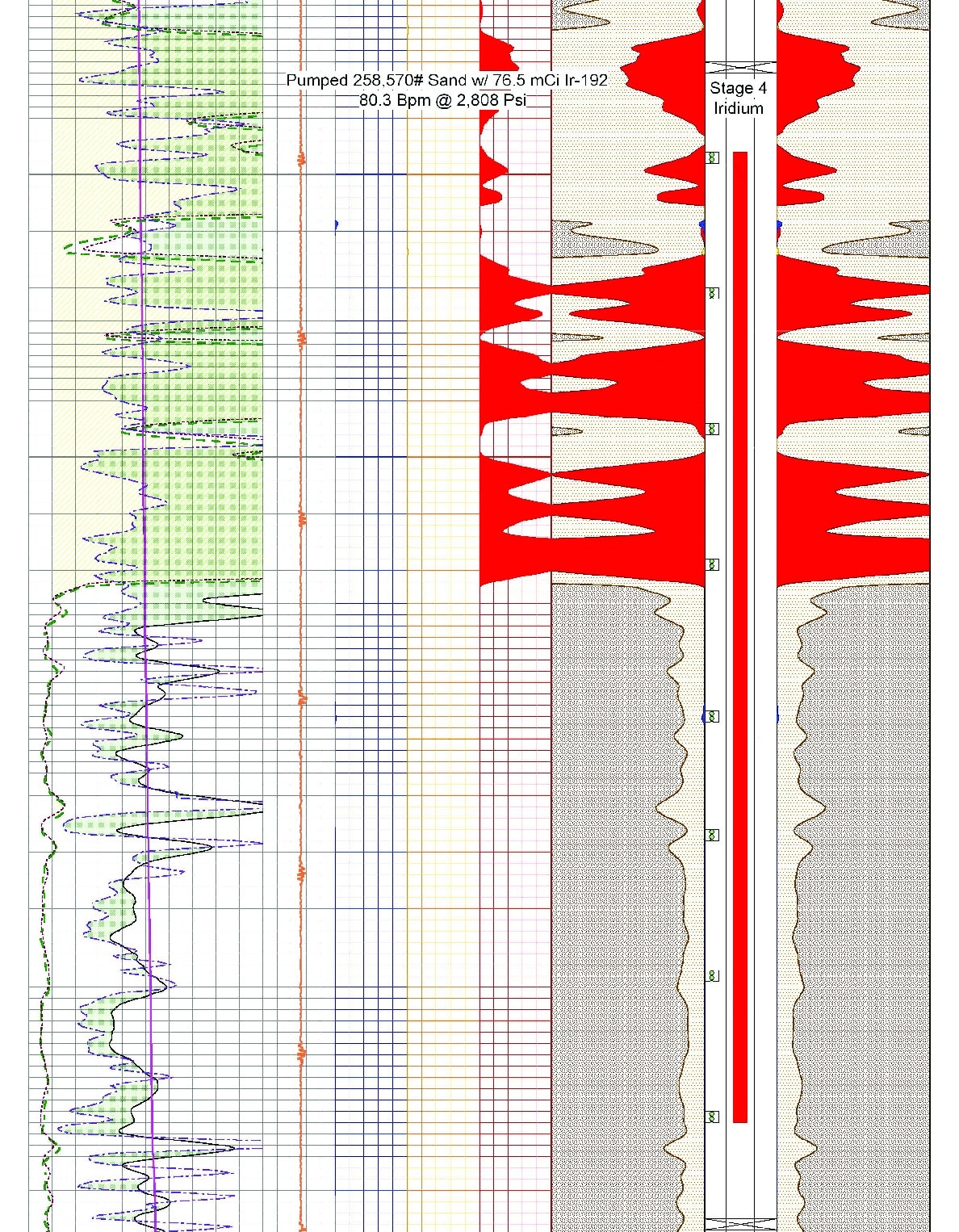

people are at the forefront of everything they do. On March 17, Renegade implemented an Employee Stock Ownership Plan (ESOP), to give employees a guarantee that they will be taken care of upon their retirement. The ESOP, established by Renegade, allows employees to become vested after three years of service with the company. At that time, the ESOP begins allocating a percentage of funds to the employee based on the employee’s salary at the time. Once the employee reaches retirement age, 65 as defined in Renegade’s ESOP, the employee is eligible to withdraw ESOP funds. The ESOP also establishes a board of directors for the business, which includes the founders of the business, Matt Gray and Randy Cassady, along with David Gray and Steve Gray.

Sham Myatt remains the company’s chief financial officer. “We hope this is going to make us a better company and it’s going to the people who deserve it,” Steve said. Myatt explained the ESOP is basically a retirement plan and is based on the employees buying back shares from the shareholders.

“When that happens, the company becomes 100 percent owned, in our case, by the employees,” Myattsaid.

The directors explained that when looking to sell the company, which has been a flagship for oilfieldcompanies in the area since its inception in 2009, they weren’t interested in selling it to a third-party oran investment group. The directors were worried an outside buyer wouldn’t take particular care of notonly the business, but the people who had been loyal to the business for so many years.

“We’ve seen the way other companies have been bought and have been destroyed after that happened,”Cassady said. “The employees now own the company through this vehicle.”

“It’s truly an employeeowned company,” Steve reiterated. “We’re selling to the people who deserve thecompany.”

Matt Gray added that another aspect of why the company wanted to pursue an ESOP is to retain controlof the company and its legacy.

“The day after the ESOP happened, nothing changed,” Matt said. “It keeps it to where we can control thecompany without a major corporate restructuring. The employees are the face of Renegade, not a CEO. It’sthe employees, that’s what really makes me proud.”

This was important to the board based on its history of being a family-run and oriented business.

“We have three things, we have customers and we have employees, and we realize that if you mess uprelationships with either one of those, you don’t have a company,” Steve said. “The third thing we have todo is make a moderate profit so we can take care of items one and two.” Currently, Renegade maintains 14locations across the United States, plus one subsidiary location in Canada. The company is also takingcare of 429 employees.

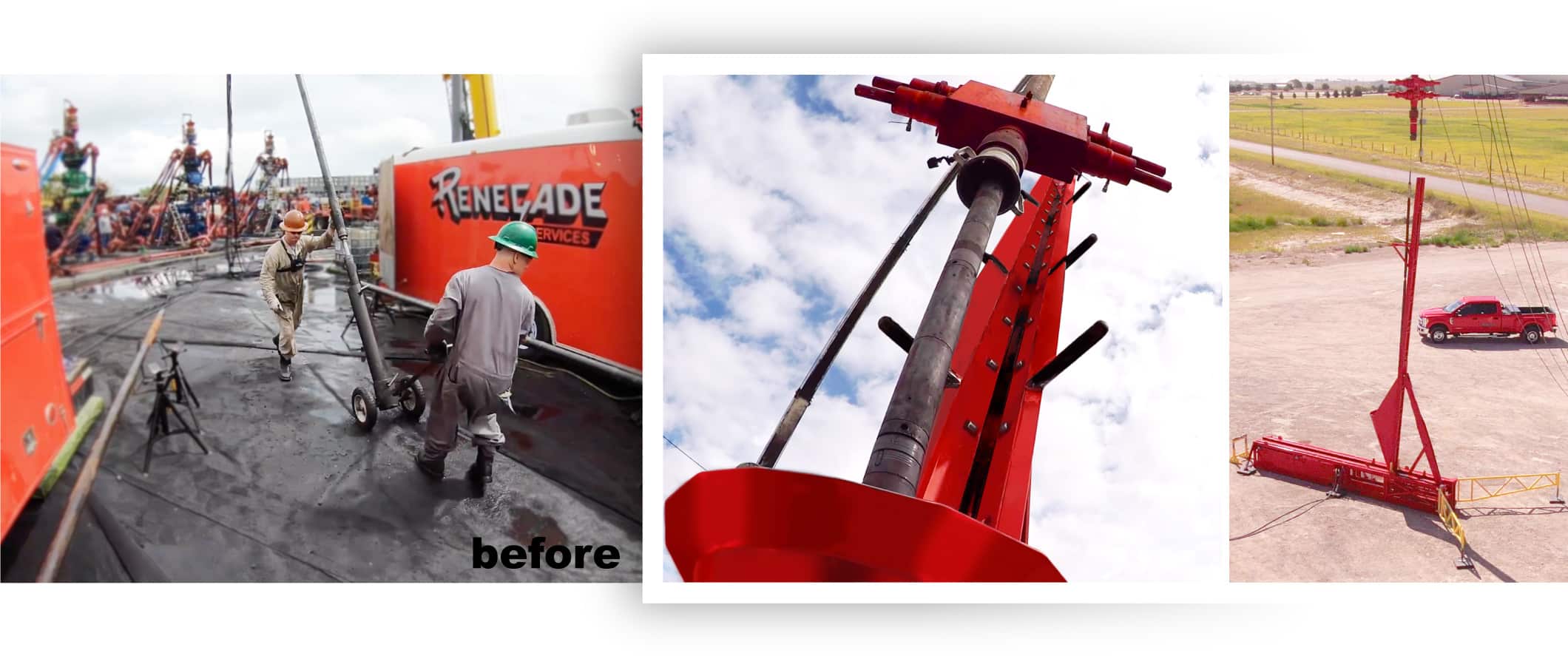

Like many other oilfield companies, Renegade faced significant setbacks after the oil crash in April 2020.Since then, the company has “clawed its way back,” surpassing two-thirds of the workforce it boasted priorto the fallout.

“We’re about 200 employees from where we were at that time,” Matt said.

After the bottom fell out of the industry, many oilfield companies, including Renegade had to step backand refocus its sights on where the industry was headed and what that meant for the future of industryleaders.

“For me it was a refocus of the founding principles of the company, which is what we’re doing as wespeak,” Matt said.

Cassady added that the company hopes that by implementing the ESOP, Renegade can continue to recruityounger employees who are ultimately the future of the company.

“We want to grow the business by bringing in younger people to help it grow,” Cassady said. “We startthem at the bottom and bring them up.”

Steve said its always been important to Renegade to be a leader in the industry. The ESOP is one way ofsetting a precedent for how business should be done. “We’re definitely the first wireline company to dothis, so once again, we’re setting the standard, we’re raising the bar,” Steve said.

The company prides itself on being the workplace for many generations with grandfathers, sons andgrandsons working for the business.

“We’re a generational company, my managers have kids who work here,” David said. “My dad is here andnow my sons work here, too.”

Most importantly, the company wants its employees to know that it’s not just something they say.Renegade is built and run by family.

“We want this business to outlive us,” Matt said.

Marketing Contact

Lesley Hoops

Director of Marketing

(970) 901-0476

Source